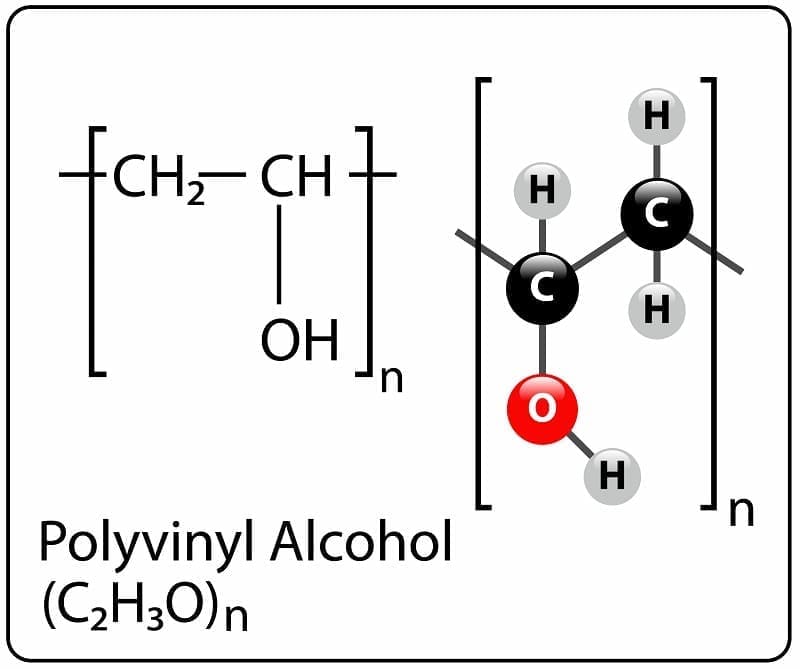

Do you know what papers, paints, adhesives, textiles, and plastic materials have in common? These items are commonly made with polyvinyl alcohol, also called PVA. This synthetic material is a colorless, odorless powder or granule. It’s also water-soluble, non-toxic, and biodegradable. Significantly, PVA is eco-friendly and approved for food and clinical use.

Polyvinyl alcohol is used as a coating, finishing, binding, and stabilizing agent in various products because of its viscosity and solubility. Some products with PVA include contact lenses, paper, sponges, laundry and dishwashing pods, shampoos, cosmetics, and disposable textiles.

This material’s chemical properties and texture give it flexibility and durability, making it ideal for many applications and purposes. PVA suppliers offer hydrolyzed and non-hydrolyzed forms with varying levels of concentration and consistency.

This material’s chemical properties and texture give it flexibility and durability, making it ideal for many applications and purposes. PVA suppliers offer hydrolyzed and non-hydrolyzed forms with varying levels of concentration and consistency.

Aside from the examples mentioned, PVA is also used in the oil and gas industry. Continue reading this article to learn more about the oil and gas applications of polyvinyl alcohol.

- Improves Efficacy In Oil Handling And Transportation

Oil and gas mined from natural resources come with varying degrees of density and viscosity. Depending on their physical properties, these substances may have different handling and transportation requirements to ensure efficacy and safety.

One way to boost efficiency in extracting and transferring natural fuels is to coat the inner portions of pipelines with PVA. Adding a coat of polymer inside the pipes will keep the surface clean, smooth, and clog-free, allowing quick movement of material as it passes.

Polyvinyl alcohol also minimizes friction and pressure while vast quantities of oil and gas constantly pass through the pipes. Hence, PVA coatings on pipes serve as protective barriers, preventing damage to a minimum.

Besides the examples mentioned, there are many other ways PVA assists in improving oil and gas handling and transportation. The use of this synthetic material can expand and evolve with technological advancements, making it even more purposeful in the mining and refining industry.

- Supports Enhanced Oil Recovery

One of the most critical uses of PVA in oil and gas mines is enhanced oil recovery (EOR). Also known as tertiary recovery, EOR involves injecting water or gas solutions into an oil resource to trigger a better yield. The process consists of injecting solutions with chemicals, polymers, gas, and other substances into the oil reservoir. Using PVA in this way is called ‘polymer flooding.’

In polymer flooding, water mixed with PVA particles is injected into the oil resource underground or mining well. Adding the solution improves the viscosity of the liquids inside the resource while increasing pressure that would push out more oil for mining.

As EOR is the third attempt to optimize the yield in a specific resource, adding a viscous agent can help extract what was left in the reservoir. The flooding agent can also break the surface tension on the topmost layer of natural fuel.

Meanwhile, it can be challenging without additional tools and power, given the quantities miners handle at a given point. Through flooding, air and liquid are incorporated into the fuel, thus allowing quicker fluid movement.

PVA flooding is beneficial to oil and gas companies in many ways. For one, it reduces the energy, time, and effort required to produce a higher oil yield. Instead of using more machinery, power, and labor to optimize oil extraction, miners can use the chemical properties of PVA to collect more oil from the resource.

Companies can also significantly save money in their operations as fuel and energy prices rise. Most oil and gas mining companies streamline specific processes by using suitable chemical substances to save on costs.

- Acts As A Foaming Agent For Drilling Fluids

Oil mining involves drilling boreholes thousands of meters onto the ground and can take days to accomplish. It could take a week or two before a complete mining setup is established in a drilling location.

Drilling boreholes for mining require powerful equipment, including the drill bit. This machine is exposed to constant movement, pressure, and friction. Therefore, it’s essential that miners use drilling fluids to protect it from damage and keep it functional.

Drilling fluids, also called drilling muds, can be water-based, oil-based, or gaseous. PVAs are used in water-based drilling fluids. Polyvinyl alcohol in powder form is dispersed in freshwater or seawater to create a slurry. Then, the resulting liquid will be pumped down the drill pipe.

The drilling mud has several purposes, including regulating the temperature of the drill bit and lubricating the bit to aid movement. It also carries the residue from the borehole to the surface to clear up space.

PVA acts as a foaming agent that helps the drill bit function smoothly. Therefore, it’s a valuable component to incorporate into the drilling liquid since it reduces the effects of pressure on the drill. Aside from this, PVA can also absorb residues and get them out of the drill’s way as it digs deeper into the hole.

- Aids In Clearing Oil Spills

Since oil is one of the primary materials handled in a mining site, the probability of accidental oil spills is high. An oil spill poses health and safety hazards to living organisms when it happens and can also put mine workers in grave danger.

Oil spills can trigger fires, explosions, poisoning, land and water contamination, and other hazardous incidents. It can be life-threatening in extreme cases, so mining companies must have an adequate response, cleanup, and recovery process in case of spillage.

PVA can be significantly purposeful when it comes to cleaning up oil spills. And because it’s water-soluble, the polymer effectively absorbs oil. Hence, it can help stop an oil spill from spreading or seeping into the ground.

After absorbing oil, cleaning up the soaked material manually or mechanically will be easy. PVA is a good cleaning agent since it’s non-toxic and water-soluble. Should there be any residue after rinsing the affected area with water, it’ll remain safe since the polymer won’t cause any health hazards in limited quantities.

Conclusion

Polyvinyl alcohol is widely used in many applications because of its unique chemical properties. PVA benefits to oil and gas companies as it aids drilling, oil movement and transportation, protection of pipelines, and clearing of oil spills.

Furthermore, this synthetic material also improves the efficacy of enhanced oil recovery procedures. PVA can be considered an all-rounder agent integral to various processes in the oil and gas industry.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.