The importance of predictive maintenance has increased in oil and gas operations against the backdrop of aging infrastructure and volatile crude pricing, according to GlobalData, a leading data and analytics company.

The company’s latest thematic report: ‘Predictive Maintenance’ reveals that the adoption of predictive maintenance technologies is helping companies cut back on operational expenditure by optimizing maintenance scheduling and driving productivity.

Ravindra Puranik, Oil & Gas Analyst at GlobalData, comments: “The insights gained from predictive maintenance program enables decision makers to schedule maintenance activities without disrupting routine production operations. These insights can also be used to evaluate if any machinery or infrastructure requires a major overhaul on priority, and accordingly decide whether to use the available capital expenditure for new projects and expansion plans or divert it for the upgrading of existing facilities.”

Predictive maintenance is a fairly mature concept and has been widely deployed in the oil and gas industry over the last 20 years. Predictive maintenance tools evaluate the condition of operational equipment and predict maintenance requirements in order to achieve optimum performance and prevent malfunction.

Predictive maintenance utilizes automated condition monitoring and advanced data analytics to gather vital equipment statistics – such as vibration, temperature, sound, and electric current – and compare them with historical records of similar equipment to detect signs of deterioration.

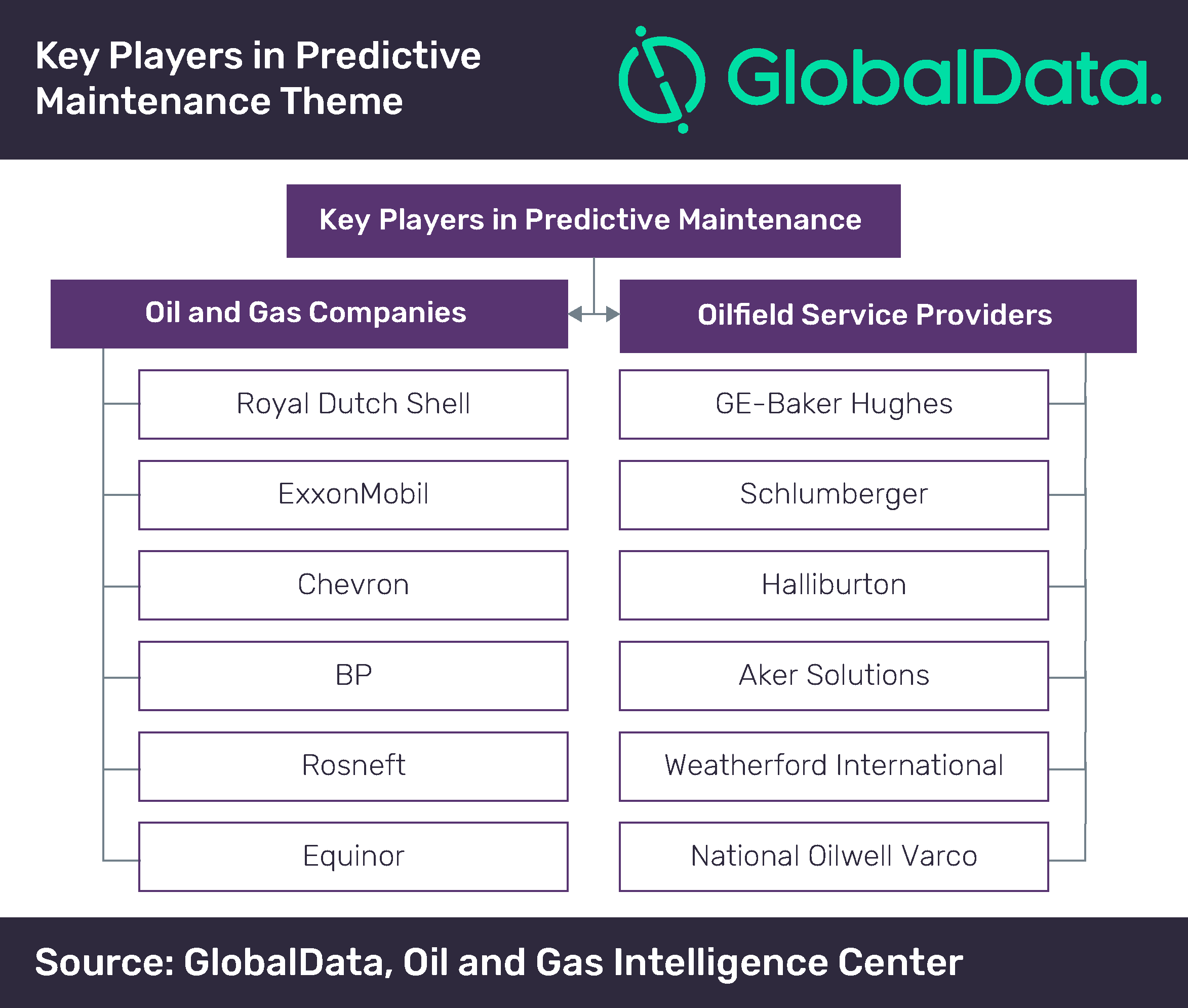

GlobalData’s thematic research identifies multinational oil and gas companies, such as Shell, ExxonMobil, Chevron, BP, Rosneft and Equinor as the leaders in the digital oilfield theme. The research also identifies oilfield service providers, such as GE-Baker Hughes, Schlumberger, Halliburton, Aker Solutions, Weatherford and National Oilwell Varco among the leading players in this theme.

Puranik concludes: “Recent advancements in cloud-based data analytics and the rise of the digital twin in oil and gas operations are extending the boundaries of predictive maintenance technologies, making it a reliable tool for monitoring asset integrity.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.