The Oil & Gas Automation and Technology Week will see industry experts sharing their valuable insights. Of all the topics, Captain Daniel Alcantara’s presentation on ‘Leveraging IIoT for Worker Health & Safety’ highlights the importance of worker safety and how Digital Frameworks using wearable technology can be deployed in Oil and Gas, and Shipping Industries.

The Oil & Gas Automation and Technology Week will see industry experts sharing their valuable insights. Of all the topics, Captain Daniel Alcantara’s presentation on ‘Leveraging IIoT for Worker Health & Safety’ highlights the importance of worker safety and how Digital Frameworks using wearable technology can be deployed in Oil and Gas, and Shipping Industries.

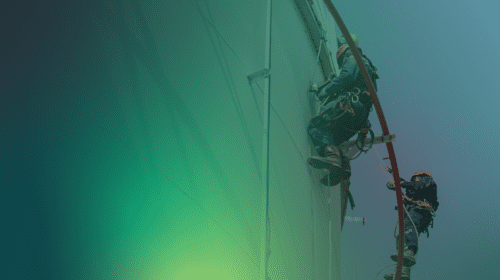

Fatal and non-fatal worksite injuries and accidents are rising in both the public and private sectors. Such accidents could result in severe personal injury or property damage. Mining, Chemicals, Energy, and Maritime are the few sectors which are prone to severe worksite accidents.

The Global Sustainability Standards Board (GSSB) issued guidelines since 2018 to develop sustainability journeys and reporting for health and safety. GSSB is the independent Standard-setting body of GRI and has developed best practices in occupational health and safety management and reporting. Despite these efforts, there is a very little change over the past decade. Worksite incidents and injuries continue to grip several sectors, resulting in a huge loss of resources.

Reasons for re-occurrence

No matter how safe a worksite is, accidents are inevitable. Companies claim that worksite incidents are on the rise for the past decade and the devastating effects result in huge human and economic costs. A global oil company claims that they have not been able to eliminate fatal incidents involving its employees and contractors.

Most companies overlook the underlying cause of the accidents and tend to concentrate on the direct causes. Accidents reoccur despite employee training and awareness programs. While these sessions educate them, it fails to guard them against anomalies and unforeseen circumstances during the actual event. It is important to take an employee’s behavior into consideration while assessing the cause of an incident.

Experts believe that certain defects in the overall safety structure of an organization could result in an unsafe or hazardous worksite. Therefore, it is imperative that the management has safety solutions backed by digital frameworks in the worksite to minimize accidents.

Transforming safety with the digital framework using wearable technology

Wearable technologies help in optimizing worker data and improving the work environment and processes. Wearable technology as a tool to curb worksite accidents is becoming popular and is adopted by various industries to create a safer work environment. They can minimize such accidents at the worksite by helping the organization with real-time alerts during an incident. Some wearables not only prevent accidents but also assist employees in their day-to-day work.

Today, wearables like SmartWatches detect anomalies and prevent accidents. Organizations can track employees working in remote and dangerous locations such as mining fields and ships.

Benefits of the Safety SmartWatch:

| 01. | Employees’ location can be tracked in remote and hazardous working conditions. This would enable the organisation to rescue employees who are stuck during accidents.

|

03. | Deliver insights on worker behaviour and provides guided intervention.

|

| 02. | Detecting heat stroke and monitoring employees’ vitals – Heartbeat and Blood Pressure help in providing quick first aid and medical care.

|

04. | Smartwatches can detect individual movements and alert them if they move closer to any dangerous location.

|

Wearables are game-changing technologies when it comes to worker safety. Equipping employees with cutting-edge solutions assist companies to fulfil their Environmental, Social, and Governance (ESG) obligations. The strategy mandates proper working conditions for the employees in any organization.

Also, owing to the increasing number of accidents, and compensations, many organizations look forward to a new technology which would help them to prevent fatal injuries and reduce claims. For organizations that emphasize on safety and well-being of employees, wearables could be the perfect tool as they are versatile and still evolving.

To know more about our DeepTech digital solutions on worker safety, follow us on LinkedIn.

Captain Daniel Alcantara is the Chief Solution Delivery Officer at Magellan X. He will be presenting at Oil & Gas Automation and Technology Week, Houston on “Leveraging IIoT for Worker and Safety” on 15 February 2023. As an expert speaker, he will highlight the importance of worker safety, and how Digital Frameworks using wearable technology can be deployed in Oil and Gas, and Shipping Industries.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.