“You have the required safety and sustainability strategy in place. That is the WHY. It is thus vital that we redirect attention to achieve the generative culture in safety to accelerate core values and sustainability results within the organization – which will bring us to the WHAT and HOW.” – Captain Daniel Alcantara

In recent times, there has been an increase in worker health and safety awareness across industries. Many employees have lost their lives due to worksite incidents and occupational illnesses. These fatalities and serious injuries are devastating and can have a long-term effect on employees, their families and colleagues. Therefore, it is the responsibility of everyone in an organization to understand the potential factors associated with worksite accidents and take preventive measures.

The Global Sustainability Standards Board (GSSB) has issued guidelines since 2018 to develop sustainability journeys and reporting for health and safety. GSSB is the independent standard-setting body of GRI and has developed best practices in occupational health and safety management and reporting. Despite these efforts, there has been very little change over the past decade. Worksite incidents and injuries continue to plague several sectors, resulting in a huge loss of resources.

While mining, chemicals and maritime are the few sectors which are prone to such worksite accidents, the oil and gas industry, a vital part of the world economy, is one of the most affected sectors among all. A report by The International Association of Oil and Gas Producers (IOGP) revealed that workplace injuries were about 10 percent higher in 2021 as compared to 2020. The prospering industry is not immune to serious injuries or fatalities.

Cause of Accident Reoccurrence

No matter how safe a worksite is, accidents are inevitable. Unforeseen events and incidents can lead to an injury or casualty. Despite their efforts, companies have not been able to improve safety records involving their employees and contractors. In fact, worksite incidents have been on the rise for the past decade and their effects may be devastating and result in huge human and economic costs.

Human reliability is one of the primary factors of workplace safety. In general, human reliability means successful performance within specific timeframes and environmental conditions. Lack of human reliability information on process efficacy and work environment increases the likelihood of accidents reoccurring.

Experts believe that by improving general awareness and understanding of the risks involved in human reliability, the rate of accidents can be brought down significantly. This can be achieved by leveraging IIoT analytics to better inform the design of employee safety awareness programs and conducting targeted, proactive training sessions.

Most companies are unable to uncover the underlying cause of the accidents and tend to concentrate on direct causes. The main reason for accident recurrence is insufficient real time information toward underlying causes and preconditions. It is crucial to obtain real time human reliability data in order to assess the cause of an incident, and subsequently execute preventative measures effectively.

Leveraging IIoT and AI technology to improve visibility and situational awareness for workers involved in hazardous operations can help reduce accidents, incidents and overall frequency. Through data and analytics, leading indicators can help management and health, safety, security and environment (HSSE) teams identify early trends and take proactive action, resulting in positive behavior change.

Unpredictable and Unsafe Behavior

Unsafe behavior of workers is one of the underlying causes of worksite accidents. Employees tend to neglect safety protocols by taking shortcuts. Also, it is common for employees to not always be conscious of their surroundings. Such unsafe behavior and a hazardous working environment can exist concurrently and cause serious accidents.

Early detection of unsafe behavior is important to execute interventions and targeted trainings. Technology plays a crucial role in detecting unsafe behavior of workers at hazardous locations. Therefore, it is imperative that management has safety solutions backed by digital frameworks at the worksite to minimize accidents.

Transforming Safety With the Digital Framework Using Wearable Technology

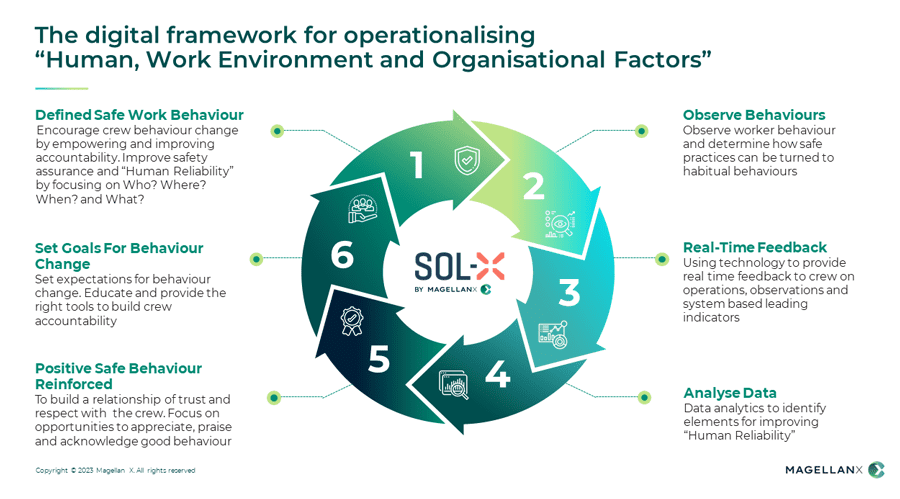

The Digital Framework

The Digital Framework

With the Industrial Internet of Things (IIoT) and software, companies can improve workers’ situational awareness. Wearable technologies help in optimizing worker data and improving the work environment and processes. Utilizing wearable technology as a tool to curb worksite accidents is becoming popular and has been adopted by various industries to create a safer work environment. They can minimize accidents at the worksite by helping the organization with real-time alerts during an incident. Some wearables not only prevent accidents but also assist employees in their day-to-day work.

Today, wearables, like smartwatches, have the capability to detect anomalies and prevent accidents. Through wearables, organizations can track lone workers in remote or dangerous locations.

Benefits of Safety Smartwatch in the Oil and Gas Industry

Location Tracking. The oil and gas industry involves specialized equipment and employees working at oil rigs and plants. Processes, like the extraction of natural gas from ocean beds, involve hundreds of laborers and engineers. Tracking workers who are spread across the site on the ocean bed is a tedious task that calls for digital solutions to connect workers and their supervisors.

Location tracking technology in smartwatches enables supervisors to track employees’ location in real time at a worksite, no matter how remote it is or how hazardous the working conditions are. A human movement overview on the dashboard and the ability to pinpoint the indicative location of workers during an emergency will accelerate rescue operations and provide swift medical aid.

Virtual Geofencing. It is impossible for management to monitor individual employee’s situational awareness with the current manual tools available and, furthermore, the topic of situational awareness has generally been misperceived as the injured person’s shortcomings (for not being situationally aware of the tasks they’ve been engaged on).

So, with virtual geofencing technology, smartwatches can detect and alert the worker when approaching a hazardous area. Over and beyond notifying the worker of direct hazards, technology can provide the supervisors with additional insights to evaluate sufficient manpower on site, workers’ work and rest hours, heat exposure, etc. We strongly believe situational awareness can be accelerated when human reliability insights become more visible or prominent.

Workforce Optimization. Unsafe acts are difficult to predict at a worksite. It is natural for workers who are on nine to 12-hour shifts on rigs to get tired or stressed. This increases the tendency for such workers to get injured due to fatigue and poor concentration. Also, the monotonous nature of certain jobs may result in workers ignoring safety protocols or behaving recklessly, causing harm to themselves and others.

As such, it is important to recognize and correct such behaviors to prevent serious accidents. Smartwatches can assist in delivering insights into worker behavior and providing the basis for guided intervention. With these insights, supervisors can make the necessary tweaks to the deployment of their workers to achieve both safety and resource optimization.

Vitals Monitoring. It is common for oil and gas industry workers to lack real-time situational awareness on hazardous worksites. Workers are unaware of pre-conditioned environmental risk exposures, and they may not receive contextual alerts that inform them of surrounding risk. External environmental factors and harsh working conditions may result in adverse physical and psychological effects.

Guided Intervention. Unsafe acts are difficult to predict at a worksite. However, it is imperative to recognize and correct such behaviors to prevent serious accidents. Leveraging on IIoT with a digital safety framework can deliver workers behavioral insights and provide guided intervention.

Social Commitments in Workers’ Health and Safety

Expectations for organizational social commitments have started to shift to focus on outcomes and not just inputs or investments. Increasingly, safety and wellbeing are becoming more important for an organization’s sustainability agenda.

Wearables are a game-changing technology when it comes to worker safety. Equipping employees with such cutting-edge solutions can assist companies in fulfilling their environment, social and governance (ESG) obligations in safety, through enhancing working conditions for the employees and reducing the occurrence of accidents and injuries.

Apart from ESG considerations, the quantum of accident claims, insurance premiums and regulatory fines for workplace injuries has increased over the years. Organizations that invest in safety technologies may well end up experiencing overall cost savings with reduced accident rates and associated costs. For organizations looking to enhance the safety and well-being of their employees, safety wearables could be the perfect tool.

Headline photo courtesy of Magellan X.

Captain Daniel Alcantara is the Chief Solution Delivery Officer at Magellan X. He will be presenting at Oil & Gas Automation and Technology Week, Houston on “Leveraging IIoT for Worker and Safety” on 15 February 2023. As an expert speaker, he will highlight the importance of worker safety, and how Digital Frameworks using wearable technology can be deployed in Oil and Gas, and Shipping Industries.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.