The Artificial Intelligence of Things (AIoT) is revolutionizing industries from consumer to enterprise with its transformative force. While consumer and enterprise segments have swiftly adapted to this technological evolution, the industrial sector presents unique challenges due to diverse operational rhythms, stringent regulatory oversight and community interest. Nonetheless, AIoT holds the potential to disrupt and transform the industrial segment including the oil and gas sector, leveraging a distinctive right-to-left approach.

The Industrial Arena Poses Unique Challenges

In the industrial sector, encompassing oil refineries, petrochemical, chemical, and various discrete and process manufacturing industries, AIoT plays a crucial role in enhancing automation and operational efficiencies. While technical challenges exist, the real complexity lies in integrating innovative approaches into the traditionally risk-averse and change-resistant mindset prevalent in the industrial landscape.

Gleaning Proven Shifts from Consumer Segment

In the realm of AIoT-driven transformation in industrial operations, many companies initially embrace a technology-first strategy, aspiring to make a substantial impact on their operations. However, they often struggle to gain the support of boots-on-the-ground operators. Consequently, they find themselves in a forced state of outside-in advisory with limited influence, rather than achieving a sustained inside-out transformation for each site operation.

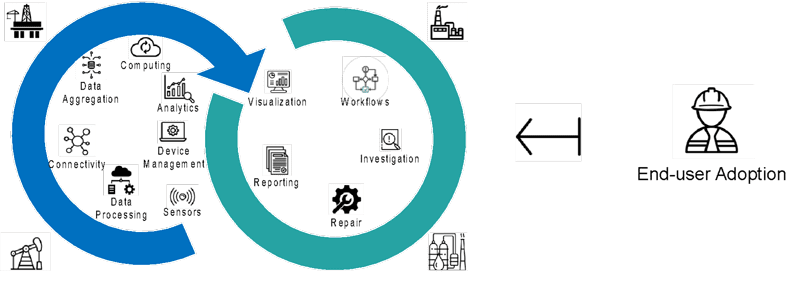

A valuable lesson emerges from the consumer segment of AIoT, where success is fueled by the excitement and widespread adoption among consumers, the end-users. This surge in adoption initiates transformative changes throughout the transformation lifecycle, ushering in rapid improvements in applications, servers, reliability, performance and security.

The industrial sector can find inspiration in the success of consumer-centric approaches by adopting a similar right-to-left strategy, as illustrated in Figure 1. This approach involves initially focusing on the individuals engaged in daily operations (end-users or operators, represented as the “right” side) and subsequently expanding the perspective to encompass the interconnected aspects of operations as a whole (broader operational aspects, represented as the “left” side). This holistic strategy aims to cultivate a more comprehensive and enduring transformation in industrial processes.

Beginning with Outliers: Unconventional Paths to Innovation in Oil and Gas

When it comes to operators overseeing remote sites in the oil and gas industry, there is an added layer of complexity. In this scenario, remote sites encompass diverse locations, far-flung facilities, or installations situated away from onsite staff. These sites routinely contend with challenging environments and harsh conditions, housing critical assets such as pipelines, storage tanks, remote terminals, pump stations and more.

In the traditional landscape of these site operations, the established practice involves adhering to scheduled inspection rounds and employing specialized monitoring systems for critical alarms. However, this customary approach proves inefficient and raises safety concerns, particularly given the vast distances that separate numerous remote sites. To truly revolutionize these operations, AIoT solutions for remote terminals must compellingly advocate for early warning systems and active operator adoption. This becomes the pivotal catalyst for initiating enduring transformation across respective sites.

Unlocking Operator Mindshare: A Proven Case Study with a U.S. Refinery

The adoption of new technology by operators hinges on the solution alignment with their existing knowledge and trust. Their daily life can be refined but not re-defined. In this scenario, the emphasis lies in empowering the operator, rather than merely showcasing sophisticated technology.

Imagine a scenario where a remote terminal operator is directed to skip routine inspections and await an alert. In this scenario, trust in the system’s accuracy combined with relevant situational awareness becomes paramount for quick assessments. These seemingly simple yet immensely significant “operator motivators” serve as the linchpin for the success of AIoT-driven enhancements in operations and maintenance.

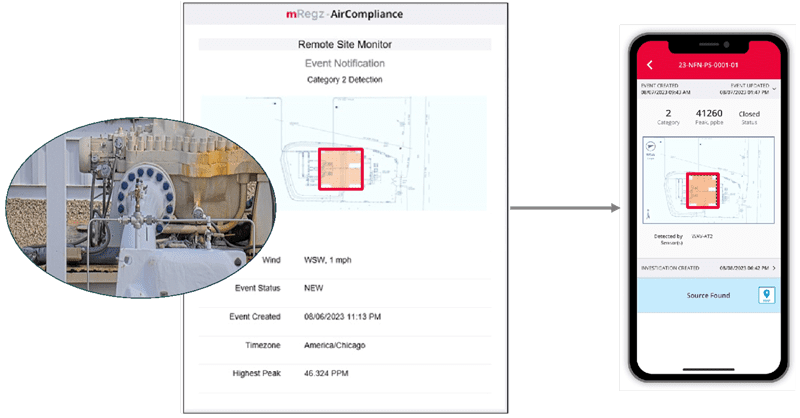

At a remote pump station within one of the largest U.S. refineries, an unforeseen emissions issue posed challenges to both production and environmental safety, resulting in escalated cleanup costs and necessary repairs. To tackle this, the refinery employed the mRegzTM AirCompliance solution enabled by AIoT technology. When an issue arose, the operations team received an immediate alert, pinpointing the problem on the site map in red (see Figure 2).

Recognizing the affected area as a gasoline pump, the operations team swiftly initiated troubleshooting measures based on the alert details. Following a thorough investigation, a field technician pinpointed a 1/2” NPT fitting leak, resulting in the spillage of approximately five gallons of gasoline. The leak was promptly addressed within seven hours. Due to the rapid response and early detection, the gasoline loss was contained to just a few gallons. In contrast, if traditional schedule-based monitoring had been in place, the repercussions could have been more severe, potentially leading to the loss of several barrels.

Unveiling Sitewide Transformation Potential

In essence, sitewide emissions monitoring transformation goes beyond technology; it signifies a fundamental shift in industrial operations and operator practices within the oil and gas and other process industries. From remote terminals to onsite areas such as process units, fenceline, tank farms, and wastewater treatment, emissions monitoring can be transformed with a holistic solution.

At its core is the right-to-left approach, empowering operators to lead a sustainable transformation across the entire site. This approach is effective in all aspects of site-wide emissions monitoring. Though alerts and responses may vary, the consistent principle is clear: It starts with operator adoption.

AIoT technologies hold immense potential for industrial transformation, but their success relies on wholehearted acceptance by boots-on-the-ground operators. Without their committed adoption on the ground, these technologies risk being relegated to a mere advisory role, detached from core operations. To truly revolutionize site operations, a profound change from within is essential – a continuous, inside-out transformation led by operators intimately familiar with the day-to-day challenges of industrial life.

Krishna Uppuluri is VP/GM IIoT Solutions at mPACT2WO, a Molex business. He has over 30 years of leadership experience in E-CAD, enterprise software, digital media and IoT software industries in Silicon Valley companies. Prior to Molex, Uppuluri was VP/GM of GE Power Conversion IoT solutions for power generation and offshore drilling industries. These IoT software solutions aggregate operations data, apply various analytics for new insights to improve operations efficiency and reduce maintenance costs. Uppuluri is the author of a book titled Engineer to Entrepreneur – The First Flight. He holds a BS in electrical engineering and an MS in computer science.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.