Continuous monitoring and rapid response to oil and fuel spills is essential for asset safeguarding and environmental protection. Recent technological advancements have paved the way for a new generation of non-contact sensors that offer enhanced detection of hydrocarbons in diverse environments, including challenging marine, freshwater, and land-based applications. These sensors also provide expanded capabilities for reliably monitoring a wider range of petroleum products, including light and very light oils.

This article explores the unique BlueHawk™ and TinyHawk™ sensors, which harness the well-established fluorometric sensing principle while introducing several unprecedented features and benefits to users. These sensors offer:

- Continuous 24/7 monitoring on both water and dry surfaces

- Unmanned operation with automated, real-time alerts

- Maintain high detection reliability in daylight, low-visibility, and dark night conditions

- Detection of all types of liquid hydrocarbons, including jet fuels and gasoline

- Long sensing range

- Broad scan/installation angle range

- Compact design, low weight and low power consumption

- Diverse range of optional features

- Exceptional value

Fluorometric Sensing, Now With UVA and UVB Bands

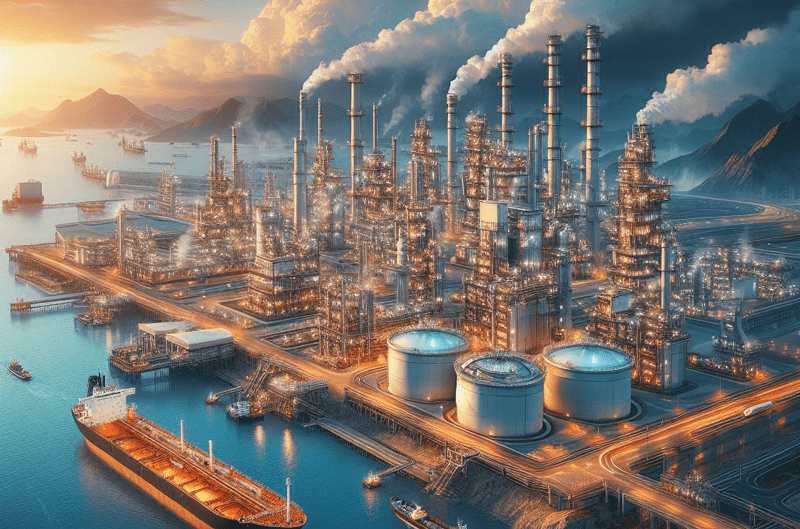

BlueHawk and TinyHawk, shown in Image 1, are fluorometric sensors that continuously emit ultraviolet (UV) light pulses onto the monitored surface. When the UV light interacts with oil or fuel contamination, it induces the emission of fluorescent light. The sensor detects this fluorescence and measures its intensity. Upon exceeding a user-defined threshold, the sensor automatically sends an alarm notification to the monitoring center for response via wired or wireless means.

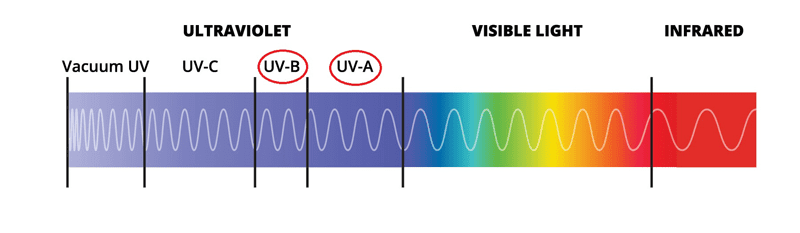

BlueHawk and TinyHawk offer a significant advantage over traditional UVA-only fluorosensors by utilizing both UVA and UVB wavelengths as depicted in Image 2. UVB is crucial for accurate detection of lighter liquid fractions. This makes them the only sensors on the market capable of reliably monitoring a very wide range of hydrocarbons from crude oils to heavyweight, medium-weight, light and very light petroleum products including gasoline and jet fuels. UVB thus creates multiple new applications for fluorometric sensing at refineries, fuel terminals and storage facilities, pipeline systems and airports, for example.

BlueHawk: The Most Advanced Fluorometric Sensor on the Market

BlueHawk, the flagship model of the Hawk fluorosensor family, boasts exceptional performance due to its patented LED-based optical design. This unique design utilizes the same large lenses for both transmitting UV light pulses and receiving fluorescence emission, ensuring very efficient light delivery and a significantly improved signal-to-noise ratio. This enhances the sensor’s sensitivity allowing the detection of even the smallest spills while virtually eliminating false alarms. BlueHawk’s design is also highly tolerant to varying surface distances, improving detection accuracy in areas with high waves or large tidal ranges, for example. Additionally, an internal health-check system using a reference detector continuously monitors and automatically adjusts the intensity of the light source, extending the sensor’s service life and MTBF as the LED ages.

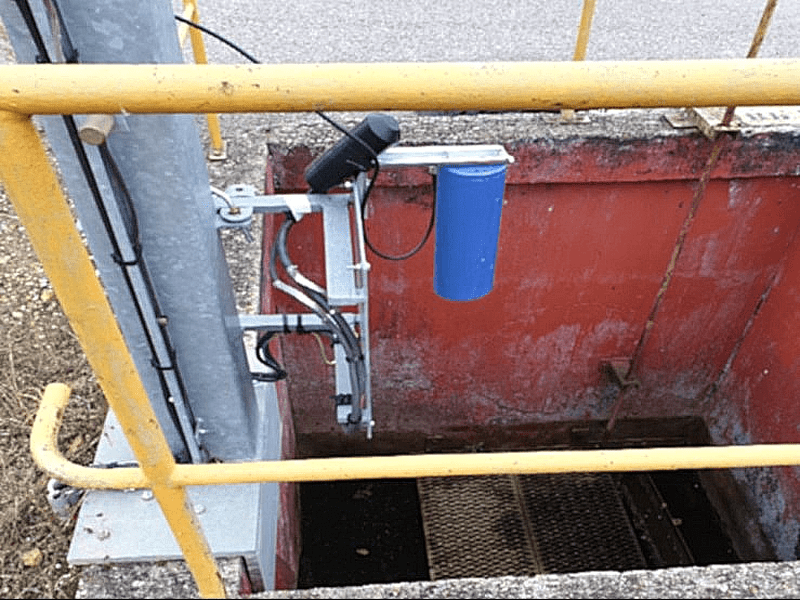

BlueHawk’s extended detection range of up to 33+ feet (10+ meters) further broadens the available applications for fluorometric spill detection, allowing for installation on distant platforms such as high docks and piers (see Image 3), canals, deep sumps, onboard vessels, and oil rigs. This is an improvement over most other LED-based fluorosensors that offer detection ranges of just a few feet.

With a high scan rate of up to 10 Hz, BlueHawk improves detection reliability in turbulent or rushing waters, surpassing the maximum 2 Hz scan rate of traditional fluorosensors. Additionally, BlueHawk offers the broadest scan/installation angle range on the market, ±45 degrees, compared to the vertical-only operation of conventional sensors. This broad angle allows for installation in cramped sumps, onboard vessels, and other environments where vertical installation is difficult or impossible. It also helps deliver improved detection accuracy in rough waters where surface topography continuously changes.

The combination of long detection range and broad scan angle enables mounting the sensor on motorized pan-tilt fixtures, allowing a large surface coverage of up to 1,600 square feet (150 m²) with a single BlueHawk, significantly outpacing the coverage of vertical-only long-range sensors.

Despite its exceptional performance, BlueHawk is remarkably compact and lightweight, making it the smallest and most lightweight fluorometric sensor with an extra-long detection range on the market. The compact design, coupled with very low power consumption, enables new deployment options, including solar-powered buoys, aerial drones (as depicted in Image 4), and other battery-powered applications.

TinyHawk: Super Compact but Still Powerful

TinyHawk, the smaller and younger sibling of the BlueHawk, is specifically designed for static surface monitoring applications that require a shorter detection range of up to 10 feet (three meters). Ideal surfaces for the sensor include concrete, soil, ice, and stationary or slow-moving waters.

TinyHawk’s design prioritizes compactness and lightweight construction without compromising detection accuracy or operational reliability. The sensor has a readiness for internal LED intensity monitoring and control functions, ensuring consistent performance and operational longevity.

Its compact size and exceptionally low power consumption of just 1.5 W make TinyHawk ideal for installation in cramped environments and battery/solar-powered applications where its detection range is sufficient. TinyHawk is not only the smallest and lightest fluorometric remote spill sensor on the market but also the most cost-effective option for building a multi-sensor spill monitoring network.

Wide Range of Optional Features for Flexible Deployment

Encased in a NEMA 6P (IP68) rated standard enclosure, as shown in Image 5, BlueHawk and TinyHawk offer unparalleled durability and watertight protection, allowing for prolonged submersion in water. Unlike traditional sensors that typically use NEMA 4X (IP66) enclosures, the Hawks can withstand even the harshest environments. Optional ATEx-certified enclosures further expand the Hawks’ deployment options, enabling operation in hazardous and explosive industrial settings.

The Hawk sensors offer versatile integration options, supporting both wired and wireless alarms. For wired alarms, they utilize serial RS485 data connection, analog 4-20mA current loop, or SPDT relay contacts. Wireless alerts via email or SMS messaging are also available with optional equipment.

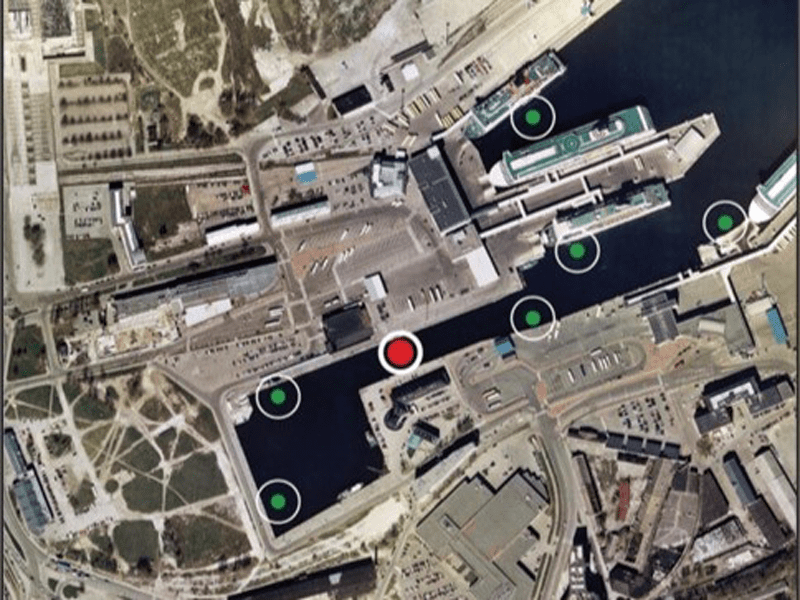

Both BlueHawk and TinyHawk can operate in standalone or networked modes, enabling up to 128 units to work seamlessly within a single easy-to-expand system. Image 6 depicts a multi-sensor system at a European seaport.

For applications with extreme sensor-to-surface distance variations, such as areas with macro-tidal ranges, the sensors can be equipped with optional surface distance measurement. This option provides real-time data on the distance between the sensor and the monitored surface, improving the sensor’s detection accuracy and optimizing its performance in such environments.

A data logger can be integrated with the Hawks to record the sensors’ digital output. This data can be used for trend analysis and spill event documentation, for example.

Special BlueHawk and TinyHawk models are available for measuring Chlorophyll-a, a color pigment found in green marine algae and phytoplankton. These sensors are used to assess the health of marine ecosystems and they can operate in the same network together with the oil detection sensors.

Recent Major Innovation

The BlueHawk and TinyHawk sensors are a recent major innovation in oil and fuel spill monitoring and prevention technology, offering unique LED-based designs, extended UVA and UVB wavelength capabilities, long scan ranges, reliable detection in challenging conditions, and flexible deployment with a wide range of optional features. These sensors can be used in a variety of different environments including sea and freshwater ports, tank farms, fuel terminals, industrial facilities, pipeline systems and water bodies from creeks to oceans.

Despite boasting industry-leading features, Hawk sensors are remarkably affordable, making them accessible to a wide spectrum of users, empowering even smaller companies and organizations to actively contribute to environmental protection and minimize the risks associated with oil and fuel spills.

To learn how BlueHawk and TinyHawk can be beneficial to your organization, please contact PhotonTec™ at info@photontec.net. Atlanta, Georgia office +1 (770) 366-4137.

Juha Saily is the founder of PhotonTec™, a newly established agency business of Techno Product, Inc. that he founded in 2001. Based in Atlanta, Georgia, PhotonTec specializes in advanced optoelectronic products, representing patented oil spill monitoring technology from LDI Innovation Ltd., a highly respected European photonics powerhouse.

Juha holds a bachelor’s degree in computer engineering from the Raahe Institute of Computer Engineering in Raahe, Finland. Prior to founding PhotonTec, Juha held various technical, sales, marketing, management, and consulting positions with several companies, including TopWave Ltd in Finland and Mexico City, Inx-Systems Inc. in Atlanta, and FocalSpec Inc. and LMI Technologies in Atlanta and Silicon Valley, California. In his spare time, Juha enjoys playing guitar and bass with blues and jazz bands in and around Atlanta.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.