Call out in text: If a picture is worth a thousand words, then aerial orthophotography (with or without vector dataset add-ons) is almost priceless.

The U. S. oil and gas industry is short about 100,000 workers, causing more and more companies to boost efficiency by remotely monitoring and controlling many operations. This allows each person to accomplish more by removing the need for daily trips to remote sites, 90 percent of which are operating smoothly. It also allows one person to make many adjustments from the office in minutes, saving hours of drive-time while improving production.

For upstream and midstream planners, the digital age is also now in session. Digital solutions like high-resolution fixed-wing aerial imagery – either “standalone” or combined with vector datasets like planimetrics – can make site planning for pads, facilities, and pipelines more efficient and save serious budget dollars.

Seeing is Believing (Savings in the Field)

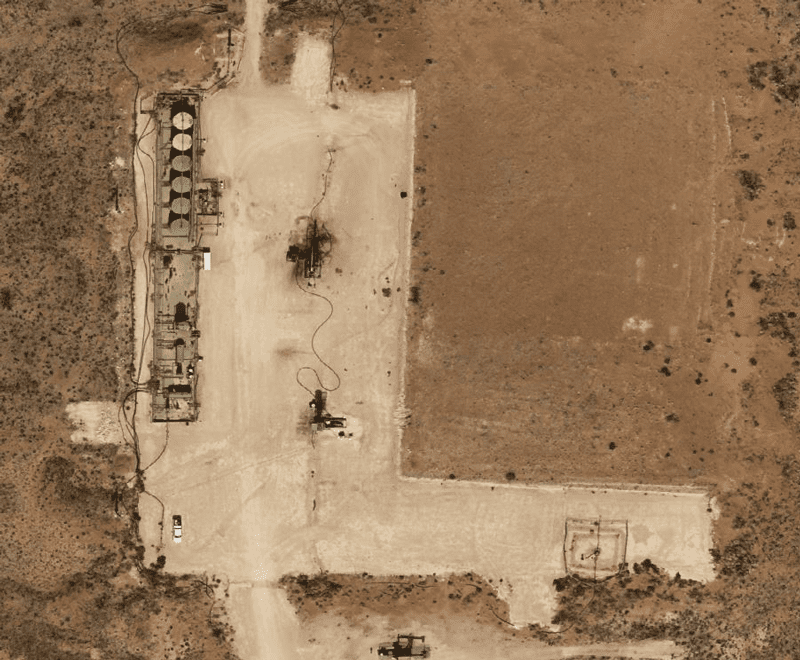

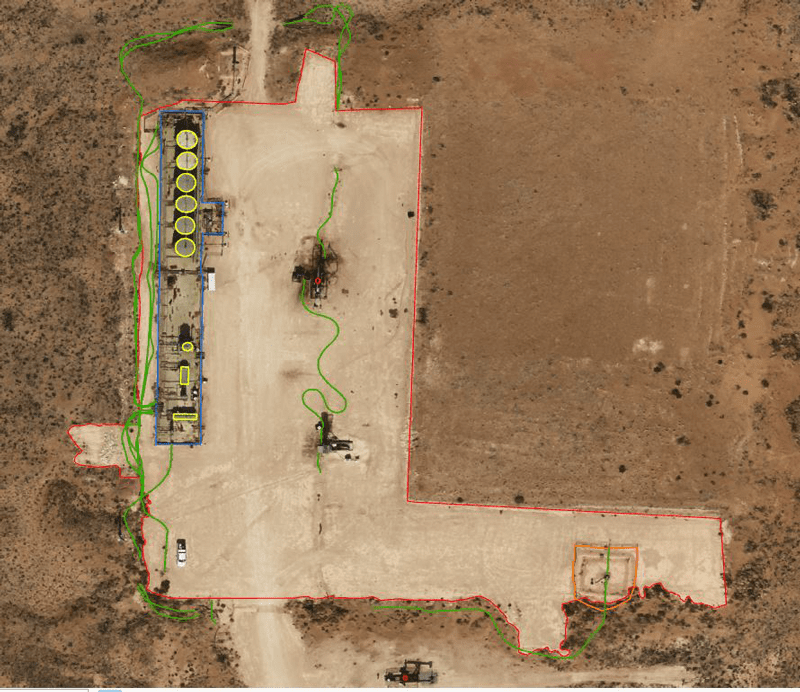

Basic aerial imagery delivers much more than the 1,000-word value by providing planners with a clear picture of the site and surface conditions. Is it crowded with structures? Are there streams or waterways nearby that would be affected in case of a spill? Where is the nearest access road? Basic orthophotography sheds easy light on those features so confident decisions can be made quickly without a site trip. It’s also geometrically corrected to remove distortions, creating a precise base map that allows highly accurate measurements.

But, as the following example clearly shows, application in the field is worth much more than any thousand words. In reality, aerial imagery can deliver hundreds of extra manhours, tens of thousands of dollars in savings, and the priceless ability to collaborate.

Over the summer a Prius Intelli client with home offices in north Texas and assets in the Permian Basin began planning to drill nearly one hundred new wells across a wide area. Travel time between office and field, either by road or air, would involve more than half a day each direction. In-person surveys in heat reaching 110˚ would have been brutal, especially over the weeks required.

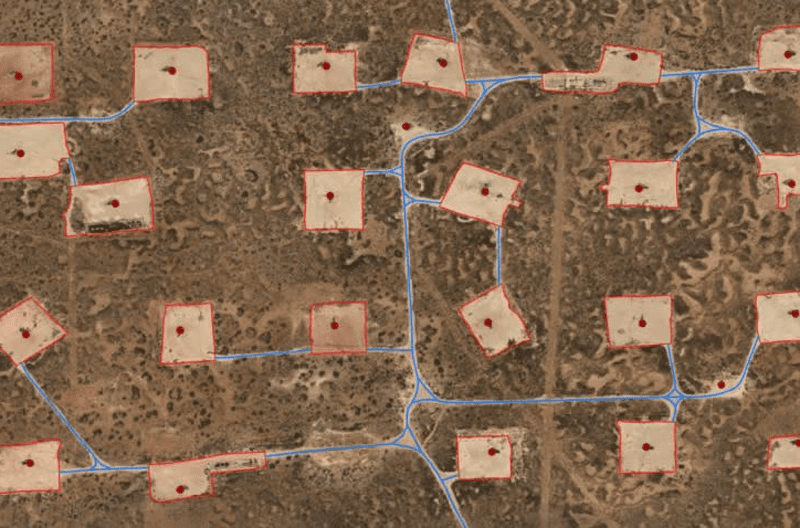

Instead, the planning team gathered in a comfortable conference room examining the site, making calculations, and coordinating plans. Using pinpoint data on pad dimensions, and distances to infrastructure like roads, powerlines, and pipelines, the design team gave potential vendors accurate information from which to formulate bids—without even the vendors needing a site visit.

All this happened in days instead of weeks or months, speeding the project’s return on investment.

Seeing is Believing (Savings Along the Centerline)

For midstream, managing pipe almost always involves distances of Homeric proportions. From a few miles of gathering lines to cross-country pipelines, aerial photography covers miles with the detail and accuracy midstream companies require, especially during the route planning phase.

A case in point is a Prius Intelli midstream client currently planning a ~250-mile pipeline route crossing under more than 1,400 individual tracts of land. Before the start of the project, the client knew that understanding the exact ground conditions would be instrumental in saving time and reducing costly surprises – exact being the operative word.

Terrain, ground cover, fences, and the presence of other structures are all major components in determining routes and assessing budgets. Some planners go to satellite data for this—but there are usually issues with that. The biggest two involve the photo’s age and the number of details present (or absent).

Structure presence could have changed drastically since a satellite’s most recent update. Outdated images can create unexpected change orders once crews arrive onsite to find a new building or fence bisecting the proposed route. And if the satellite photo’s detail is insufficient, objects like fences or small buildings may be invisible.

Prius Intelli’s client eliminated these potentially expensive planning roadblocks with a strategic fixed-wing flyover of several routes under consideration. In addition to dollars saved from identifying and side-stepping costly problems, they greatly reduced the need for boots on the ground. Their available manpower was freed up to focus on operations.

Because planning can take months or years, many changes can happen during the process. Therefore, many midstream companies schedule aerial photography twice—at the beginning of planning, then again before breaking ground, to catch any last-minute changes. The two photographs can be compared in order to identify differences that might require changes in planning.

Upping the Visual Value

Besides providing a precise bird’s eye view of an Area of Interest (AOI) for better planning, more value can be added to everyday aerial imagery by adding derivative vector datasets like planimetrics. A planimetric map involves the digitization of two-dimensional features (both natural and man-made) on the Earth’s surface. Used within GIS software systems, or even Google Earth, the map provides exact locations of these features. For regulatory compliance regarding buffer zones between wells and buildings, this information is critical down to a few inches. Many regulations require a 350-foot buffer around buildings, depending on their type.

From client input for each project, Prius Intelli collects imagery and digitizes the features into shapefiles. Typical features created include:

- Well Pads

- Roads

- Telephone/Power Poles

- Fences

- Structure Outlines

Midstream, PHMSA Compliance, and Planimetrics

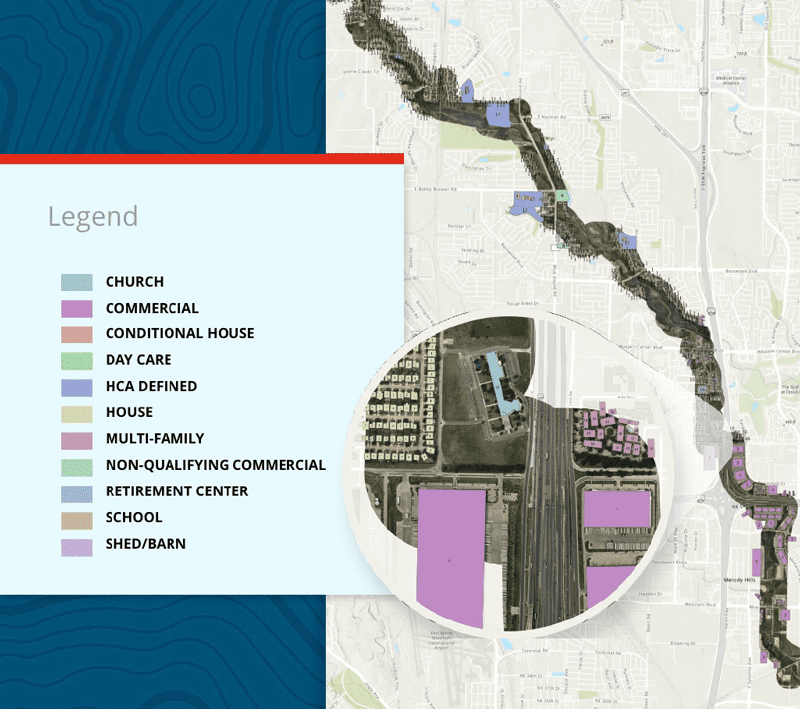

Recent rule updates from the Department of Transportation’s Pipeline Hazardous Materials Safety Administration (PHMSA) have expanded the types of areas considered high impact, requiring midstream companies to reevaluate existing classifications. Aerial photography is an efficient solution, especially with planimetric mapping added in.

For structures, it’s not just the presence—it’s the number and the type. PHMSA’s job is to make regulations ensuring pipelines transport hazardous materials safely across their entire length. Densely populated areas require greater safety measures than do open or rural regions. To do that, PHMSA has created class designations for “High Consequence Areas” or HCAs. Classes 1 and 2 are for rural areas and Class 4 indicates a location with dense population including residences and health care facilities within a certain distance of the pipeline. Class 4 pipelines require greater safety measures.

Prius Intelli’s Structure ID combines a high-resolution aerial survey with planimetrics and classification efforts, helping identify and label homes, apartment buildings, hospitals, schools, and other buildings that determine an area’s PHMSA class. To do that, RGB orthophotography centers along the centerline of the pipeline, after which structures within the pipeline’s defined buffer are digitized for easy recognition. Then those structures are identified according to PHMSA population density guidelines.

Because this process involves one overflight, after which data is typically delivered within 4-6 weeks, as Environmental Systems Research Institute (ESRI) databases or shapefiles, it shortens the turnaround time by weeks, and greatly reduces costs.

Time Change

With a shortage of skilled workers in the industry, companies are leveraging digital solutions like aerial imagery to boost efficiency, reduce production costs, and improve site planning. As the industry continues to face labor shortages and cost pressures, the benefits of aerial imagery will likely become increasingly clear, making it a must-have tool in any planner’s toolkit. In all these ways and more, aerial photography (with or without vector dataset add-ons) is worth much more than just a thousand words.

Headline photo: Adding planimetric vector datasets to the imagery can pinpoint the presence and location of surface structures to help in site planning. Photos courtesy of Prius Intelli.

Ethan Sparks is Vice President of Geospatial Solutions for Prius Intelli, having joined the company at its beginning in March, 2020. With more than a decade of GIS experience, Sparks helps the company create new solutions and use cases for imagery and data, in order to solve clients’ data requirements. He has degrees in Geography and Math from the University of Texas.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.