Oklahoma’s Anadarko Basin, one of the world’s super basins, is currently known for horizontal drilling in the Woodford Shale, the principal source rock in the basin. However, above the Woodford, many attractive oil and gas reservoirs have been pursued with vertical technology over the past 100 years. As one of the deepest basins in the United States, with horizontal Woodford wells routinely drilled between 14,000 to 17,000 FT TVD, there is a lot of rock above the source in which hydrocarbons have accumulated.

Lynx Oklahoma Operating is focused on developing targets for horizontal drilling within and adjacent to existing legacy fields in the Anadarko Basin, specifically Caddo County, Oklahoma. After analyzing multiple targets in Caddo County, including the deep Woodford, Meramec, Springer, Red Fork and multiple Hoxbar reservoirs, Lynx decided to initiate its horizontal program targeting crude oil in the Hoxbar Marchand. The Hoxbar Marchand is a sandstone oil reservoir with a typical gravity of 42 to 48 degrees API at 9,500 FT to 10,500 FT TVD, historically developed utilizing conventional vertical technology since the mid-1960s.

Legacy vertical Hoxbar Marchand wells vary in performance. Many are marginal vertical producers and vertical wells drilled but never completed for various reasons, including reservoir properties deemed commercially unproductive, commodity prices and operator challenges. Lynx’s Chief Executive Officer Nelson Bolen states, “These variables provide an attractive dynamic when analyzing conventional reservoirs for modern horizontal unconventional development, as the vertical penetrations provide a detailed subsurface database, showcase producibility, but leave most of the oil behind.” Although vertical Hoxbar Marchand development was in thicker, clean sandstones and thinner, dirtier sandstones, prospects in the thinner, dirtier rock were often not developed beyond the first few wells. This provides an opportunity to add value utilizing modern unconventional technology on legacy conventional rock.

According to Al Warner, senior vice president of geology, “Lynx’s geological approach was to first construct a series of detailed cross sections wherein individual sandstone benches, generally 5’ to 25’ but, in some instances, up to 50’ were correlated. These individual benches were then mapped over their entire extent, providing targets that, in many cases, extend beyond the known limits of a given field or play. In a number of instances, this detailed ‘splitting’ of the sandstones included mapping and extending the shalier sandstones over broader areas which have proven commercially productive.”

When targeting sandstones, like the Hoxbar Marchand, the gamma ray log is not the gospel when identifying productive or nonproductive rock. Other factors must be considered during drilling to stay in the optimum interval. Hydrocarbon shows both gas and oil provide excellent evidence of potentially productive rock, but are not always easily identified, especially when drilling with weighted oil-based mud. Rate of penetration is another excellent leading indicator that is utilized during geosteering and for target changes.

Targeting the best rock is critical for success, with a focus on staying in the clean sandstone and shaley sandstone intervals. Lynx has seen equally good shows in both of these sandstones and selected black, organic, high gamma ray shales within the Hoxbar. The Woodford has been interpreted as the primary source for hydrocarbons within the Pennsylvanian reservoirs, including the Marchand, but the black shales may not only be a secondary source but could also contribute to production, particularly if they are in close association with the sandstones; thus providing additional upside. Lynx has not drilled a pure Hoxbar Shale well, but it could provide significant upside in the future. Lynx’s current focus continues to be the Hoxbar Marchand Sandstone interval.

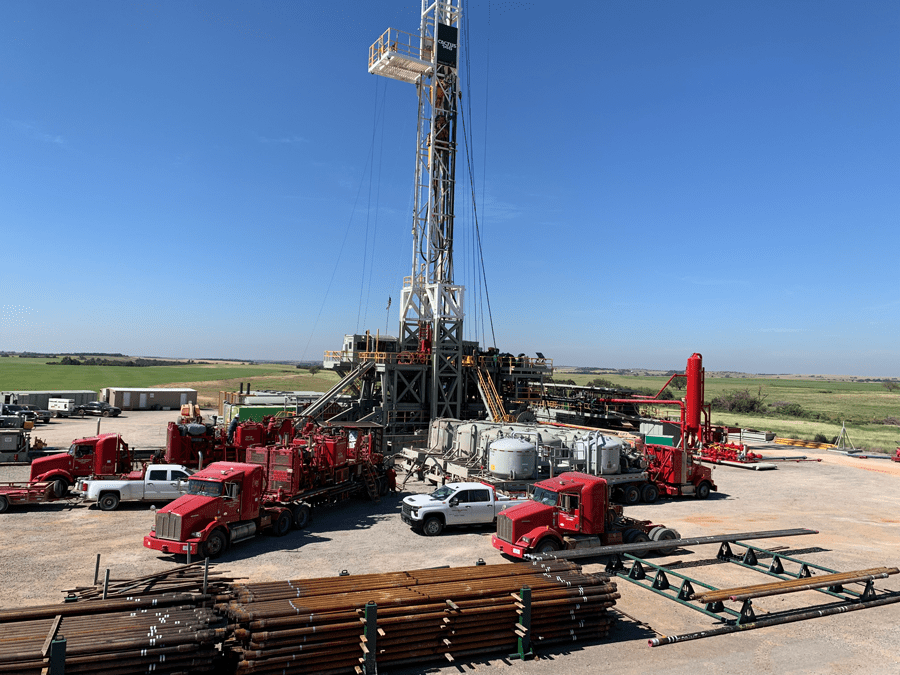

By optimizing drilling practices, the mud system and BHA, Lynx successfully eliminated the intermediate 7” casing, commonly run in this area. This allowed Lynx to utilize a monobore design, 5.5” casing from surface to TD, enabling fracturing rates at 100 BPM under 10,000 psi treating pressure, further reducing costs, and allowing for increased frac design optionality. Currently, Lynx is performing plug and perf operations with 200 FT stages, including two diversion drops per stage.

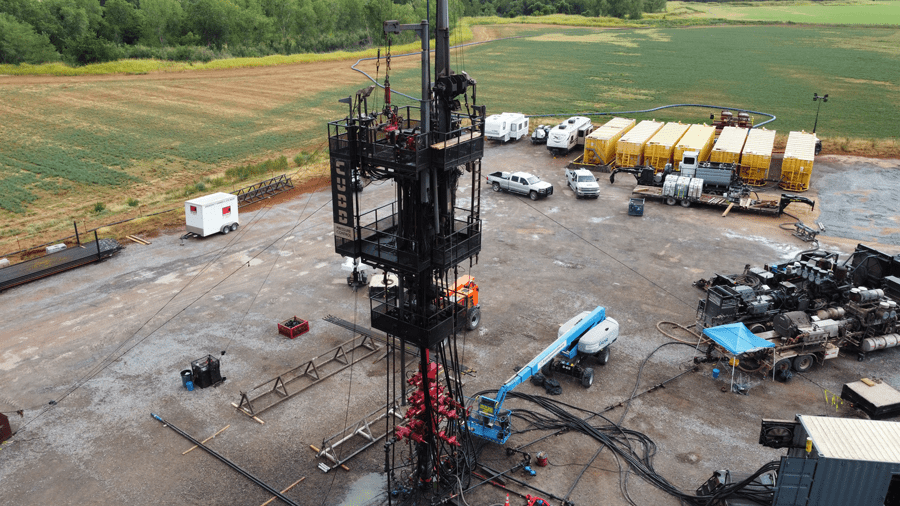

Lynx recently finished drilling Sergeant Major #1HXL, one of the longest horizontal Hoxbar wells at ~20,000 FT MD with a 9,500 FT MD lateral. A combination of composites and dissolvable frac plugs were utilized to reduce completion risk. Lynx drilled out all plugs to TD and did not see the dissolvable plugs during milling or plug parts at surface, indicating the technology performed as designed. The next step in Hoxbar completion evolution is to increase proppant volumes. Currently, Lynx is placing 1,800 lb/ft proppant. While monitoring offset wells during fracturing, Lynx does not see any pressure interference at 600 FT spacing.

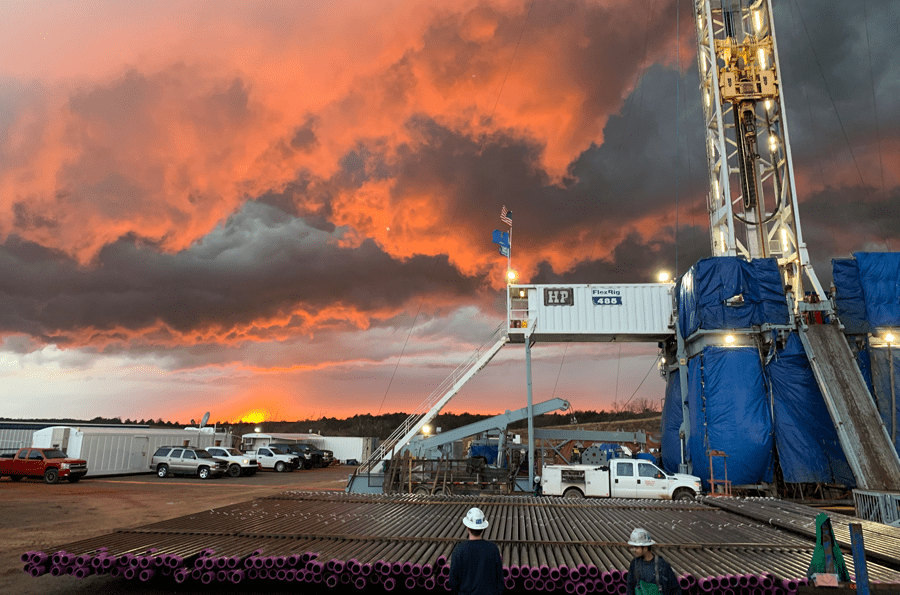

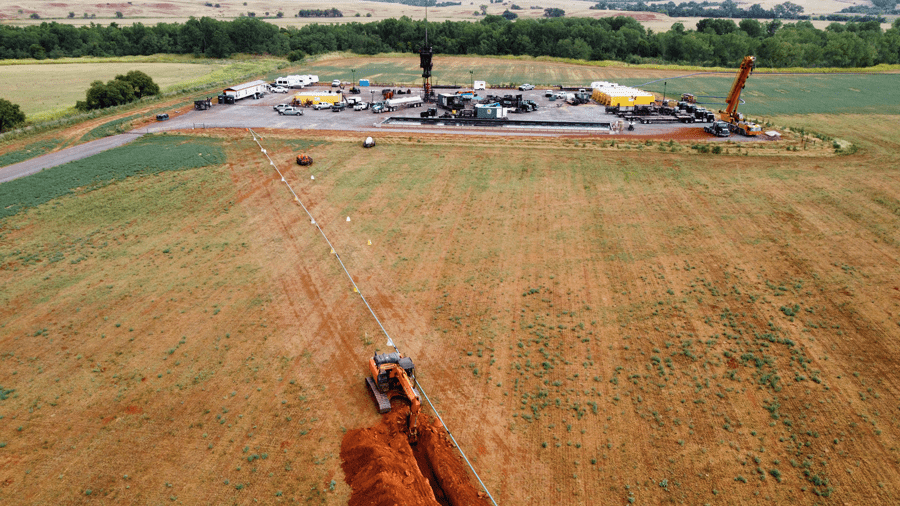

Headline photo: Winter sunset at TD. Tripping out while preparing to run 5-1/2” production casing on Lynx Fleet Admiral 21-16-10-11 #1HXL.

Matthew Hatami is the chief operating officer of Lynx Oklahoma Operating, an Oklahoma based oil and gas operator, and a licensed professional engineer with 22 years of experience. Prior to Lynx, he was vice president of resource development at American Energy Partners and American Energy Global Partners. He also worked as a senior asset manager at Chesapeake Energy Corporation and in corporate strategy and planning at Hess Corporation. Hatami holds a degree in petroleum and natural gas engineering from West Virginia University and an MBA from Columbia University.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.