Wyoming-based Encore Green Environmental Technologies and Licensing (EGETL) began with a dream of taking a former nuisance substance – produced water – and turning it into an asset for use in restoring rangeland in dry western states. This would benefit producers, landowners and the climate/environmental, social and governance (ESG) agenda equally.

Its goal was threefold: To help producers manage produced water, to provide soil health assistance for 21st century landowners in arid oil producing areas and to restore the sometimes acrimonious relationship between landowners and E&Ps.

The benefits would be extensive. Instead of sending 90 percent (approximately 10 percent is reused for hydraulic fracturing) of the millions of barrels of produced water into saltwater disposal (SWD) wells – which may be linked to anthropogenic earthquakes – it could be used in conjunction with soil testing and extensive planning to bring life to drought-stricken range and farmland in dry western states, often on the very land from which the water was produced. With ESG demands rising, an agriculture application that would boost soil health and plant growth to the point of improving carbon capture would check all boxes. It could also reduce groundwater consumption for irrigation.

Historically, the catch for remediating produced water for such use was always cost. Encore Green has studied the treatment requirements of produced water in various basins and understands cost effective pretreatment. It just needed a last step – desalination – to make it work for agricultural purposes. For the first two years of the program, it had relied on third parties for various desalination systems. Doing it that way had several challenges, including the fact that systems were not always reliable or cost effective.

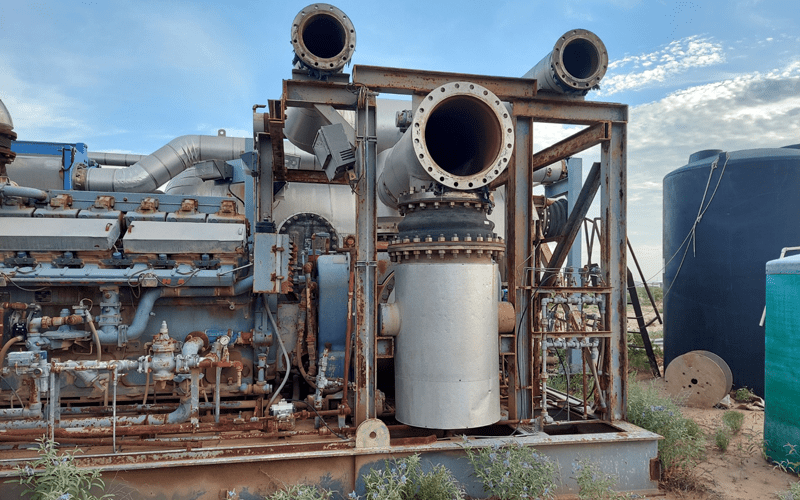

When XRI/Fountain Quail made its NOMAD system available, it was apparent that this effective but dormant technology would be a perfect fit.

NOMAD History

Fountain Quail had developed NOMAD in the late 1990s to satisfy demands of early hydraulic fracturing processes. Those systems required fresh water, which strained groundwater supplies in competition with municipal and agriculture use. Using produced water seemed necessary.

Existing desalination options were inefficient and costly. Membrane separation systems removed much of the total dissolved solids (TDS), total suspended solids (TSS), sand and others. But they were very costly to run and maintain, and filters quickly became fouled, allowing residue to damage equipment.

Desalination is best done by evaporating and condensing the water, leaving impurities such as salt to be flushed out separately. It leaves the water very clean. But standard systems require great amounts of energy to boil the water, making them expensive, if efficient.

To reduce the amount of heat required, Fountain Quail engineers developed a three-stage process to recapture and reuse heat already in the system. Categorized as a “mechanical vapor recompression thermal evaporator,” NOMAD uses steam to heat the incoming stream of produced water. Since both the heating agent and the product are steam, all the heat can be recovered and recycled.

At the beginning of each operating cycle, the unit requires heat only for the starting sequence. Heat is both conserved and created in two ways. NOMAD creates additional heat by forcing the produced steam into a mechanical vapor recompression operation. Compressing steam (or any gas) increases its heat content.

In addition to the heat from compression, NOMAD’s heat recovery process conserves the original energy input as follows: By using steam to boil the incoming water, heat from both the treated flow and the waste stream can be recovered and reapplied to the process. This eliminates the need for further energy to be expended for heat, making the NOMAD uniquely cost-effective in converting produced water for use in farm and rangeland operations.

A thermal evaporator offers advantages even to the pre-treating process. Unlike membrane desalination, technology is not affected by organics in the feed water. This eliminates the need for costly oxidative pretreatment. NOMAD typically requires just TSS removal via clarifier, dissolved air flotation (DAF) or the use of scale inhibitors when sulfate scale is expected in the waste brine system.

Why Was a System Like This Available?

With all of NOMAD’s advantages, the energy industry soon realized it needed much more frac water than evaporation could produce. So fracturing processes were developed that could use less-processed water, and after effectively treating more than 30 million barrels, the system was idled.

That allowed EGETL to purchase the research and the equipment for much less than its face value, making it the perfect fit for their goals.

Making ESG Work

Simply putting clean water on the ground, even in plains and deserts west of the Mississippi where much of the nation’s oil is located, was not enough. EGETL formulated a plan and created other resources to allow producers, landowners and the climate to benefit the most.

More and more 21st century landowners are looking beyond just receiving a check for royalties or surface use. EGETL has observed that many are looking to leave a legacy for their descendants – and that means improving the land.

On the other side, industry giants planning to reforest swaths of Europe or other continents must wait decades for trees to grow big enough to capture enough carbon to offset their production, and small-to-medium enterprises need a reasonable and useful option that meets their criteria.

EGETL created the Carbon Asset Network (CAN) as a partner for these parties. Soil samples taken at two levels – 0”-6” and 6”-24” – by an agronomist are the start. These are sent to a certified laboratory to determine baseline levels of organic carbon, nutrients and other parameters at both depths. Currently, popular use of satellite images can get only surface level readings, and even that is done more by computer modeling than by actual tests.

With this data, the grower and the agronomist agree on a course of action, which involves application of treated water to boost organic growth.

CAN is not a carbon credit program; rather, it is a resource for progressive stewards of land looking for input on soil restoration.

EGETL’s Role

Calling itself “an agriculture midstream company,” EGETL’s goal is connecting landowners with producers needing to dispose of produced water and boost ESG scores; [this] is EGETL’s business model. The company uses water and, where available, flared gas to negotiate a service use agreement. Sometimes this agreement results in the landowner taking less cash in exchange for first right of refusal for any excess water from wells on their property.

For other parties interested in ESG beyond producers and landowners, EGETL created Synergy for Ecological Solutions (SES). SES allows those individuals or groups to donate money, which is then apportioned to progressive landowners working with CAN, who may not have the resources to implement soil restoration plans themselves.

Green Future

Today, 90 percent of produced water is pumped into SWDs, a process that has been identified with increasing earthquakes. A cost-effective alternative that benefits agriculture, ESG concerns and air quality seems perfect. As EGETL updates NOMAD, renaming it NOMAD Excel, this will meet all those criteria in the green future.

Darren E. Smith, chief technology officer for Encore Green Environmental, has spent his career handling and advising on environmental, health and safety (EHS) issues in the oil and gas industry. He has worked on corporate issues such as reducing climate-affecting emissions, protecting endangered species, effectively/safely treating produced and other issues. He advises EGETL in water treatment technologies and environmental, social and governance (ESG) business opportunities for clients.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.

1 comment

Comments are closed.