As I think back to my years growing up in Uvalde, Texas, then attending the University of Texas at Austin, my path to the oil and gas industry has taken many interesting twists and turns. My first introduction to computers came back in 1985 playing a game on an Apple IIe in high school. To my recollection, that experience did not inspire me to want to learn more about computers. The true inspiration that drove my desire to learn about computers started while I was attending the University of Texas at Austin and taking an intro to programming class. The computer language, Pascal, taught the programmer programming structure, logic, creating functions and procedures. These basic principles continue to drive our logic – no matter how complicated. Programming and logic seemed to come to me naturally; now I have evolved and learned how to apply business logic and rules.

Learning these skills came from working in the international logistics industry, more specifically the international freight forwarding. I started by creating glorified form fillers that were mapped to specific shipping documents, such as a bill of lading, air waybill, dock receipt, certificate of origin, notice of departure or other various documents. Each document was a separate application, so the process was not efficient because the user had to re-enter data each time and no data passed from one document to another. Within a few months, I figured out the best way to share document information based on the shipment mode of transportation and whether the shipment was an export or an import. As the application was maturing to meet the operational aspects of the freight forwarding business, additional demands came in for quoting, managing booking requests, tracking inventory, invoicing customers and managing the costs related to the shipment and the costs for running the business. The demand for one integrated solution became evident and CDM WinFrt was born. The application was derived from an up-and-coming graphical user interface operating system and the international freight forwarding industry.

Through the late ‘80s, to the ‘90s and the 2000s, CDM WinFrt grew to include project cargo and connectivity to U.S. Customs. The project cargo module would eventually become my introduction to the oil and gas industry – more on that later. In Houston, Texas, project cargo among the freight forwarding industry has been a thriving industry for decades; however, the process of handling and managing project cargo is document intensive. The freight forwarder must manage the purchase order from the primary shipper that can be linked to hundreds of suppliers. The forwarder then manages the receipt of materials against the purchase order, then arranges the transportation of the goods to the project’s destination.

It was a frantic Friday afternoon in December 2009 when a high valued shipment bound for the Mid-East was accidentally shipped to South America. Little did my customer know it at the time, but it would cost nearly twenty million dollars to recover the high valued shipment. My customer approached us with a challenge: Would it be possible to prevent this from happening again? At that time, radio frequency identification (RFID) was slowly gaining momentum in certain industries but not oil and gas. The problem was that RFID did not work well around iron. We gathered all types of RFID labels and tags, testing each label and tag on the individual items and on the pallets that contained the items shrink wrapped in black plastic. After several months of testing, we rolled out our first RFID solution. Our RFID solution was simple: We installed fixed RFID readers and antennas at the dock doors, then the user would assign a dock door to a specific project cargo reference number. Each pallet or loose item related to the project cargo contained a RFID label. As the pallet or item passed through the RFID antenna, a green light or red light would illuminate right above the dock door. This visual indicator would prove to be very beneficial in the first year, possibly saving my customer millions of dollars in losses.

Within the oil and gas industry, finding the right solution has proven to be a significant challenge. Barcodes were a limited option; however, the rough environment of the yard and rig site would destroy or cause the barcode to detach from the asset. This one-way tracking would prove to be costly and extremely inefficient. Radio frequency identification (RFID) technology had come into prominence over the past ten to fifteen years. One of the biggest challenges for tracking assets utilizing RFID is simple physics. Iron, iron and more iron; RFID cannot penetrate iron and iron causes significant deflection to the RFID signal.

My customer promoted this solution to many oil and gas service providers, then one day my customer’s customer asked if we could help them track individual items or assets. They had very little experience with automated data capture such as RFID, IIOT, IOT and GPS. We put together a presentation that explained the invention of barcodes through the evolution of the industrial internet of things (IIoT). In order to meet the customer’s requirement, we designed a RFID tag that would withstand the harsh environment and the constant beating, as the iron would be tossed into metal cages, then transported from the yard to the job site. This RFID tag was encased in sturdy steel and capable of being read on either side of the tag. This provided maximum visibility as the asset was scanned during the loadout, scanned into service, scanned out of service, then scanned back at the yard.

The evolution of the software would become CDM Asset Tracking™ and provide additional benefits, such as incorporating functional testing of the iron, tracking iron certification, tracking iron utilization and non-utilization and, most importantly, recovering chargebacks on washed iron.

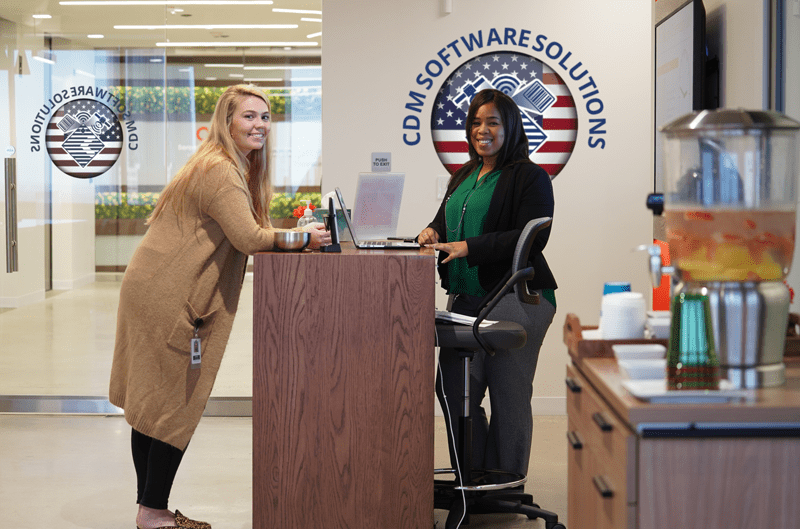

CDM Software Solutions has dedicated itself to helping oil and gas companies manage and track assets through a digit twin.

Darrell Ortiz attended the University of Texas at Austin from 1986 to 1988. He founded CDM Software Solutions, Inc. in 1988 with global headquarters in Houston, Texas, with additional offices in Los Angeles, Miami, Scottsdale, London and Hong Kong. Ortiz has grown the company for nearly 35 years, including certifications with U.S. Customs and U.S. Department of Defense, primary software application solutions for global logistics shipment management, including U.S. Customs shipment compliance and creation of CDM Asset Tracking™, an industrial internet of things (IIOT) and RFID asset tracking solution specifically configured to meet the demands of the oil and gas industry.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.