While technology and innovation have paved the way for improvement in the oil and gas industry, they have also responded to mistakes made along the way. A more effective method of rectifying the error has manifested from lessons learned in the loss of life, asset damage and environmental disaster.

This sentiment has been no more evident than in the actions taken after Hurricane Ivan invaded the Gulf of Mexico in 2004. The devastating storm wreaked havoc and caused an underwater mudslide that led to Taylor Energy’s Mississippi Canyon (MC20) Saratoga platform, a 550-foot-tall structure, literally falling over, resulting in the longest continual domestic oil spill.

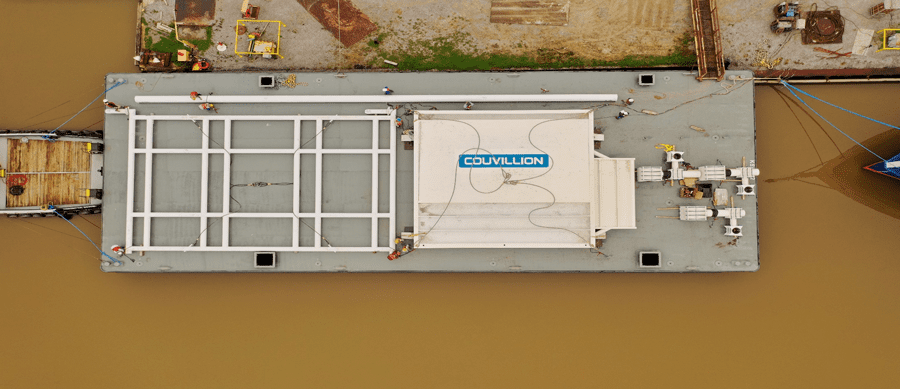

As of today’s date, oil and gas still exit the seafloor and would be contaminating the environment to devastating standards, if it was not for the efforts of the United States Coast Guard and the Couvillion Group, LLC, located in Belle Chasse, Louisiana.

The process of dealing with the spill has been long and arduous. It was not until November of 2019, 15 years after the incident occurred, that Couvillion had the opportunity to assess the situation and devise a corrective action plan.

“It wasn’t just a small accounting of microns, but a pit of oil the size of a tennis court,” says Timmy Couvillion, president and CEO of the Couvillion Group, when referring to his first visual made of the aftermath. “It made my skin crawl.”

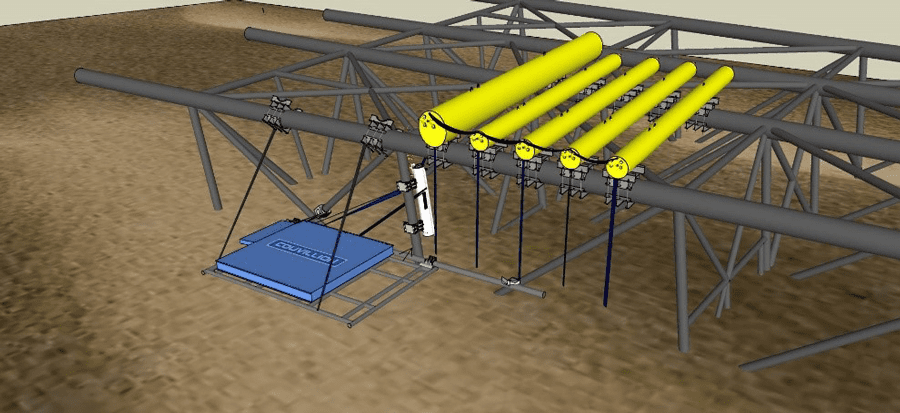

Adding to the challenge of containing this spill, Couvillion was tasked with designing and fabricating a system that would serve as a rapid response solution. At that moment, the goal was not to stop the leak but instead contain and collect the oil spewing from the seafloor. A 40 feet x 40 feet subsea collection dome was fabricated and lowered from a support vessel. It was then fastened to Taylor’s inoperable platform jacket laying on the seafloor. The dome was suspended approximately seven feet above the four plumes of oil and gas being expelled from the seabed. This height was selected as a countermeasure to avoid clogging.

A mixture of oil and gas, or hydrocarbons, is directed through the dome and into a subsea separator, extracting oil from the remaining gas and water combination. The oil is sent to subsea oil containment vessels, and its offloading is processed monthly employing a submersible hydraulic pump, and the oil is transferred to a surface vessel. It is then transported shoreside where it is recycled.

When the oil is pumped off, reports are drafted and made available to the public. An accurate accounting by barrel count is presented, which subsequently defines the significance of the spill itself. Couvillion Group’s first pump-off report indicated that from April 12, 2019, to April 23, 2019, 17 barrels of oil a day had been collected. This equates to 715.7 gallons per day. As of December 3, 2021, the latest pump-off report reconciles those 18,705.3 barrels of net oil that have been collected. (This is also identified as 785,622.6 gallons.) By the data levied, the approximation of two years has seen a staggering quantity of oil collected that would have otherwise left a devastating blow to Louisiana’s coast as well as the sea life inhabiting the area.

Defining the efficiency of the Couvillion response is made possible through sheen reports sourced from the National Oceanic and Atmospheric Administration (NOAA) satellite imagery. Effectiveness is based on the size of the sheen so, if it is large, one can deduce that oil is spilling or leaking. A smaller surface area regarding the Taylor spill indicates that Couvillion’s containment system is functioning at an ideal expectation.

According to Couvillion, when his company’s containment system was put into use, its effectiveness rate was measured at 96-percent. As the years have progressed and the Couvillion system has continued, slight improvements have been implemented.

Initially, upon implementing the containment system, sediment was immediately identified as a potential future problem. As a result, the company added a multi-directional flushing system to prevent the obstructions caused by sediment buildup.

Additional methods and component improvement have also assisted in streamlining the process. Couvillion has changed handles on valves and added quick connections where needed.

“We started at 96 percent effective and today we sit at 99 percent,” says Couvillion.

While the gas is vented off, that recycled oil goes to a facility in Berwick, Louisiana. Through the arrangements of the deal wagered, the U.S. Coast Guard and the Couvillion Group are partners in ownership. They, therefore, benefit from the sale of the recycled oil, but Timmy Couvillion says his company has not kept any of that money.

“We give all of that money to charity,” says Couvillion, who exhibits great passion and generosity with the Teacher of the Year program at Belle Chasse High School.

Timmy Couvillion recounted the monumental task his company undertook to source this project. He described it as having many moving parts. “Within six months, we designed, fabricated and installed a system that worked. We even tested it in my backyard swimming pool.”

Considering the severity of the spill and the significance of the response, most would bestow accolades toward the commitment exerted by the Couvillion Group. The publicized data supporting its collection efforts can only speak the truth in the level of pollution produced and the success made in containment, but this was not the case when it came to the Taylor Energy response. While the company was a pillar of the oil and gas sector in Louisiana and gave back in various facets, its response appeared to counter that sentiment. After years of clashing arguments, the federal government took over, but Taylor was not ready to whisper “uncle.”

In addition to suing the federal government, Taylor also levied a lawsuit against the Couvillion Group alleging that the company was trespassing when it connected its containment system to its fallen platform. This was in addition to other arguments made, all while MC20 Saratoga had been resting on its side at the bottom of the Gulf of Mexico for the past 14 years. In 2008, Taylor Energy sold all of its assets, and ceased all drilling and production operations. Its current existence today is directed to MC20 response only.

Technology and innovation will be called upon to permanently plug and abandon these Taylor Energy wells that continue to dispense the unwanted oil. The site of MC20 Saratoga is in a heavily traveled shipping lane. In addition to the marine life affected by the spill, ships have had to sail through the oil as well. Plug and abandonment would eliminate its effects forever.

To carry out such a mission will require exceptional thought, engineering innovation and geological study to render a solution that will succeed in the same fashion as the Couvillion Group’s containment plan. Like many other industries, the oil and gas sector has learned how the combination of skill and innovation can produce effective responses to issues, even those which leave behind painful sheens of failure and regret.

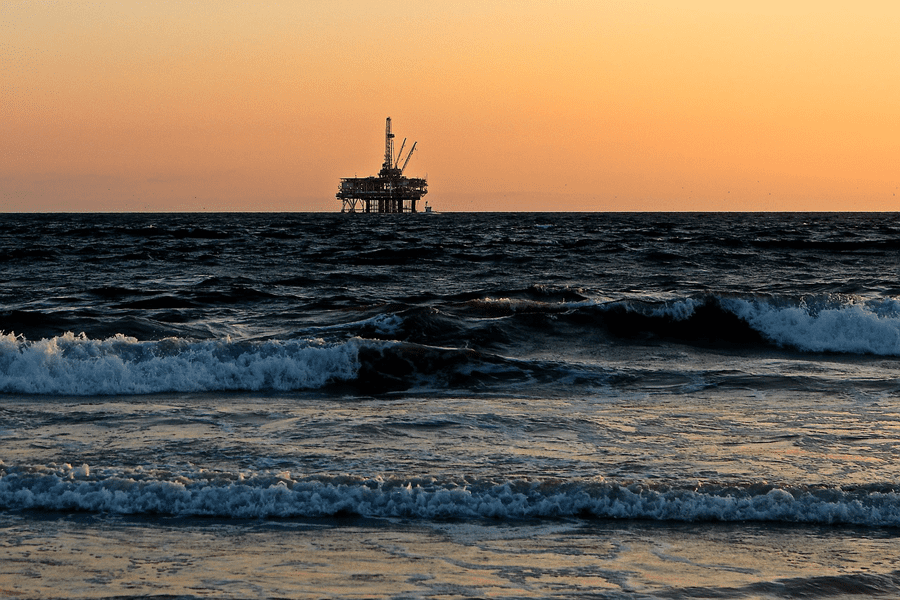

Headline photo courtesy of Pixabay

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.