Humble roots in service, that’s how MEYER started. Helping our customers when their equipment broke down. Listen to the problem; fix the problem. But as we listened, things changed…

Customers wanted to know:

- Could we make them more efficient?

- Could we grease their operation faster?

- Could we keep their guys safer?

- Could we build something to help them achieve zero – zero equipment damage, zero incidents, zero downtime?

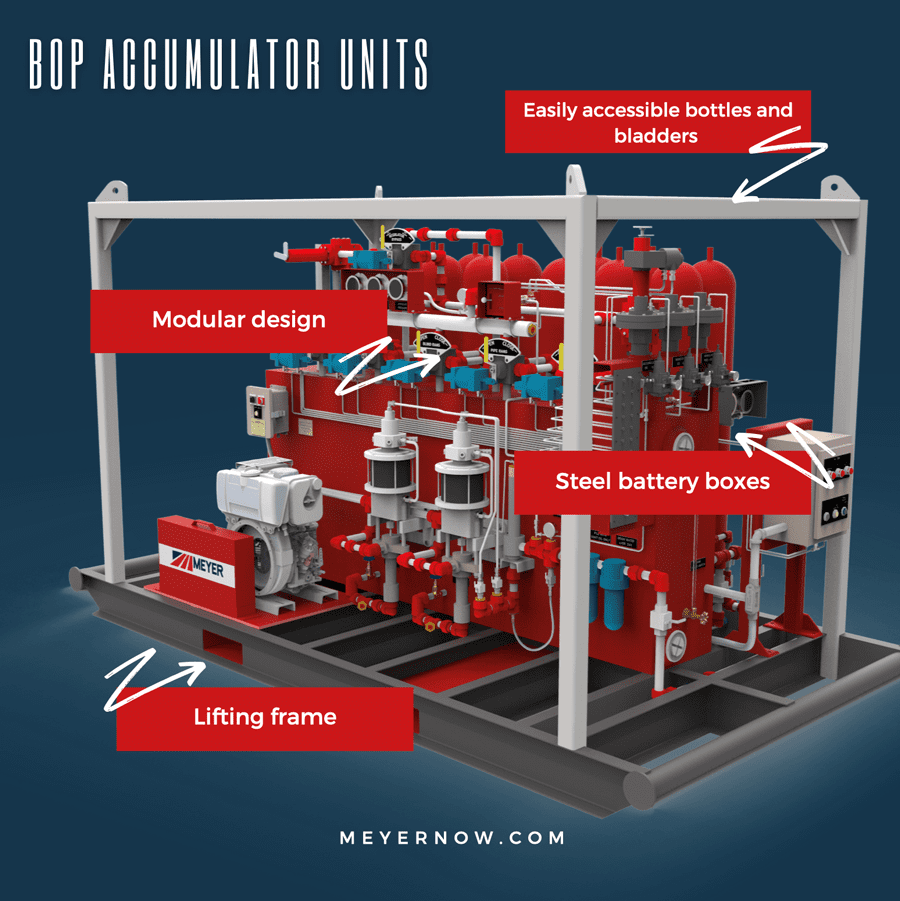

We built a BOP Accumulator Unit with an Auto-Start Box for zero parasitic power drain.

We built a fully automated Greasing Manifold to achieve zero man-hours in the red zone.

We decided that all our products would be built in-house, in the USA, with zero outsourcing, and zero latitude for failure.

We built revisions, and variations, and add-on products until our customers were satisfied, and then we kept going.

Today, we have powerful in-house design and manufacturing capabilities throughout the great state of Texas.

We have one of the largest and most experienced service teams in the industry, so no matter where you are or what type of equipment you have, we can get you serviced.

Our rental fleet is expanding daily, our team continues to grow, and we’re driving technological and safety advancements at a lightning pace.

All in the name of customer success.

We’re still a service company, at heart. We’ll never lose the drive to do whatever it takes to ensure our customers are winning. That’s always been our mission, but today the mission looks a bit different.

“We leverage some of the most advanced technologies around the preventive maintenance and lubrication of valves and fracs. As such, we have been able to increase safety and decrease cost, always striving to ensure zero red zone exposures, zero downtime, and massive reductions in NPT and maintenance costs,” says Noel McKim, MEYER’s engineering manager.

MEYER has revolutionized the fracking industry with its proprietary SPYDER® Grease technology, best illustrated by its success story of a 150-stage frac in Haynesville. The client was experiencing failures in five out of six valves, resulting in 36 hours of NPT and significant revenue losses. MEYER’s equipment solved the problem quickly and efficiently, eliminating any further valve failures and washouts while drastically cutting back on their revenue losses.

MEYER’s SPYDER® Grease technology has saved the industry millions of dollars, increasing equipment uptime and boosting efficiency overall. As MEYER continues to expand its technologies and make breakthroughs in the industry, it is clear that there is no limit to its potential as it continues to redefine successful fracking.

MEYER is proactively positioning itself to stay ahead of the curve as companies increasingly invest in smarter, more automated processes. MEYER is looking to enhance communication and increase data acquisition and analytics capabilities in order to help clients make more informed decisions. MEYER is also researching how remote monitoring and predictive analytics can help clients ensure proper well control even in challenging environments. MEYER’s commitment to staying abreast of industry trends and providing solutions that meet its client’s requirements truly sets it apart.

Allison Meyer, a Baylor Business Administration alum, has worked for her family’s business, MEYER, for over 10 years and is thrilled with the technological advancements MEYER is making in the oil and gas sector.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.