The oil and gas industry has historically inspired innovation and technological advancement. With so many service companies populating the market and offering the latest solutions to the most current problems, competition remains tight with customers left to determine which fix should commandeer the budget. As a result, service companies must be quick to identify a need and then present a solution promising success along with fiscal responsibility.

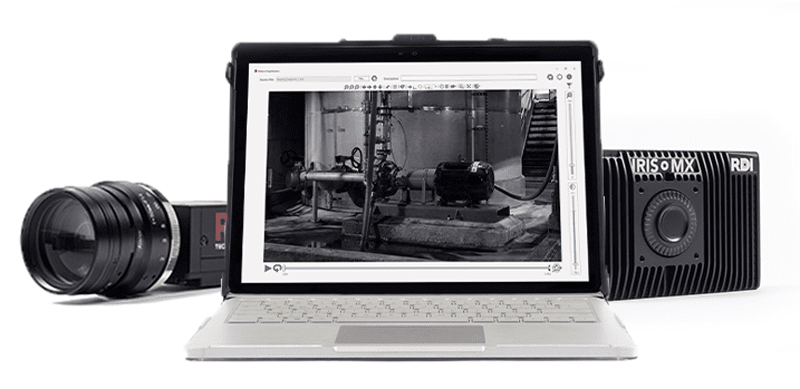

RDI Technologies enters the industry as a solution provider, but with an edge. While others contemplate how to persuade the customer and justify solution importance, RDI Technologies subscribes to the simple but true thought process of seeing is believing, all made possible by Motion Amplification®. The secret resides in RDI Technologies’ ability to enable users the ability to evaluate motion that has only been measurable by the human eye in the past using contacting sensors. Combining the use of its IL Series High Speed Digital Camera | Fastec Imaging equipment and RDI Technology’s Motion Amplification®, statistical data represented through charts and graphs is now replaceable by video data. Video empowerment provides users a path in efficiently and effectively evaluating complex problems with an equally quick and safe turnaround time in communicating any issues discovered.

RDI Technologies enters the industry as a solution provider, but with an edge. While others contemplate how to persuade the customer and justify solution importance, RDI Technologies subscribes to the simple but true thought process of seeing is believing, all made possible by Motion Amplification®. The secret resides in RDI Technologies’ ability to enable users the ability to evaluate motion that has only been measurable by the human eye in the past using contacting sensors. Combining the use of its IL Series High Speed Digital Camera | Fastec Imaging equipment and RDI Technology’s Motion Amplification®, statistical data represented through charts and graphs is now replaceable by video data. Video empowerment provides users a path in efficiently and effectively evaluating complex problems with an equally quick and safe turnaround time in communicating any issues discovered.

“Our technology is the very spirit of seeing is believing,” says Paul Barna, regional sales manager with RDI Technologies. “It is 100 percent safe and effective, allowing our customers the ability to quickly identify problems and identify valuable data.”

What is Motion Amplification®?

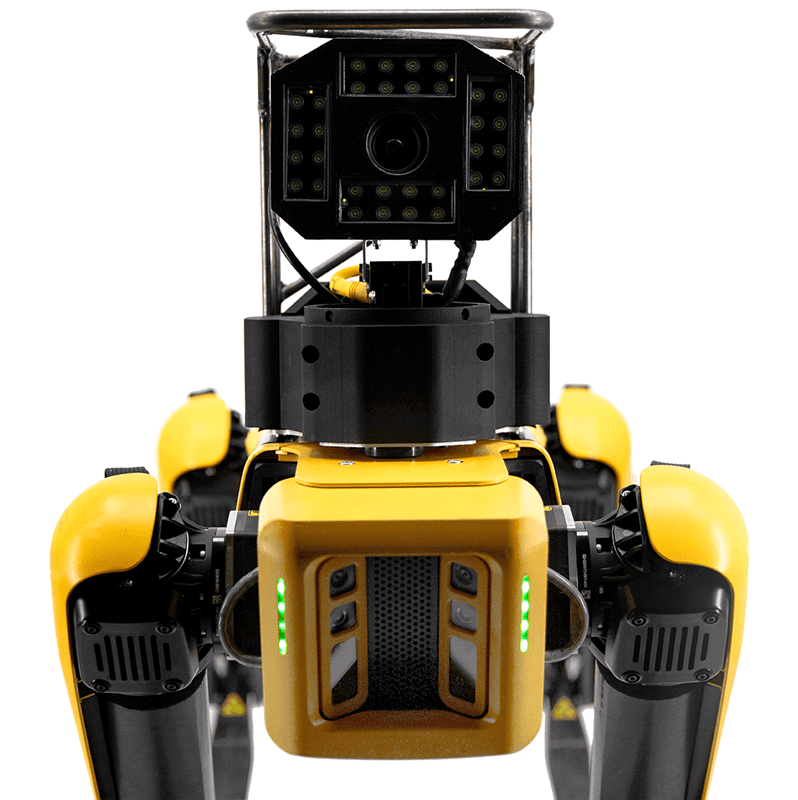

Motion Amplification® technology concentrates on securing measurements in movement, deflection, displacement and vibration undetectable by the human eye. Ability and power are made possible by utilizing every pixel in the camera’s viewfinder as sensors of measurement. Each pixel plays a part in taking measurements; therefore, an increase in pixels increases the accuracy available in determining those measurements.

Even the most subtle of movement is detected and converted into footage that can be interpreted by the user. Because the data is captured in video footage format, it is easily communicated to others. RDI Technologies’ Motion Amplification® software allows the user to customize the video footage at specific frequencies to best provide interpretation and m anipulation of the data retrieved.

The true benefit of this innovative tool is the ability to quickly capture the data allowing it to be analyzed immediately. This provides the user the ability to expedite arriving at the root cause quickly, which leads to cost savings in time discovering the issue, and then responding with an effective solution. RDI Technologies provides a solution that sees no challenge from competitors and has proven to be successful across multiple platforms of use.

Multiple Software Platforms

Motion Amplification® includes multiple formats of its software to provide the most effective solution needed by each customer. Its first non-contact software platform came available as Iris M and instantly provided a vantage point not detectable by the human eye. The root cause became more easily identifiable, and the platform was introduced to industrial markets. Iris M serves as a viable solution in various areas of interest that include operations, process lines, manufacturing machinery, quality components and structural components.

The Iris M software allows the user to visualize all aspects of the process while securing component level analysis. Respectively, this software package is matched perfectly for screening assets of various sizes, finding faults, commissioning new equipment, and even in repair and retrofit applications. Video footage captured enables discovery of movement to the smallest degree which serves in exponential ways in evaluating and repairing assets.

RDI Technologies took a successful software platform in Iris M, instituted improvements and increased capabilities, to make them available in the Iris MX software. Designed for high speed applications, Iris MX brings the capability of executing an astonishing thousands of frames per second. This allows for comprehensive study of high-speed machinery without shutting down.

RDI Technologies responded to the need for continual study with Iris CM, a continuous monitoring application and solution. This application utilizes multiple pieces of equipment to portray a multi-vantage point depiction of what is occurring with a particular asset. Each camera operates simultaneously and stores up to 90 minutes of data on each camera. Recordings can be triggered both physically and through virtual camera-based sensors.

Revolutionizing the Oil and Gas Sector

In identifying where Motion Amplification® could provide benefit, the oil and gas industry certainly becomes a target-rich environment. This capability possesses the potential to offer immediate resolutions throughout the industry. The technology is available in two different options.

“Our goal is to sell the product to our customers,” says Barna. “If our customers lack the talent and resources, we can provide the service to them and take the video footage where they tell us it is needed.”

The oil and gas industry contains multiple areas that include working components that are subject to failure. While failure is undesirable, it is a reality that must be managed. RDI Technologies’ Motion Amplification® offers the prospect of identifying potential failure before it occurs. Whether discussing pipelines, compressor stations or other process equipment, a loss of primary containment, known in the industry as an LOPC, signifies hazardous income. Potential impacts to people, property and the environment can be severe in the event of a spill.

Oil and gas professionals can use Motion Amplification® to detect potential leak points. While compressor stations command significant rates of horsepower, engines run continually. That vibration resonating through every connected component can compromise connection points. Spool piping can loosen and result in an unwanted LOPC. Through implementation of Motion Amplification®, operators can see that vibration travel through compressor equipment while a regular glance or study by the human eye would be unable to make the identification. Through video footage, compromised bolt up connections suffering from severe vibration can now be seen. Connections can be tightened before succumbing to vibration, and loss time and spills can be avoided.

The hydraulic fracturing industry offers a plethora of opportunities where RDI Technologies can apply Motion Amplification®. Hydraulic fracturing systems are engineered with various equipment demanding a robust amount of energy consumption. Multiple pumping trucks are needed to move fluids to meet demand. Additionally, a large supply of piping is necessary to serve as the path of transfer regarding those fluids. Multiple connection points can fail.

While pump trucks move fluids, connection points at trucks and manifolds can fail due to the level of vibration following the flow path. Motion Amplification® technology can identify the level of vibration traveling hydraulic fracturing piping and the effect it has at those connection points. By identifying hazardous vibration at the manifold, spills can be avoided instead of corrected. Severe vibration rates identified by RDI Technologies software can point professionals in the direction needed to tighten or re-torque connection points before they fail. Loss of product on the ground drives additional costs, which leads to a loss in potential profit.

The new oil and gas industry focuses on key factors. Increase in profits is earned through reduction in non-productive time or NPT. Work must be conducted safely, and attention must be given to lowering the carbon footprint. Motion Amplification® can serve customers in all of these areas.

“From a financial point of view, Motion Amplification® offers a huge savings in time and money,” says Barna. “We’re talking about tens of thousands of dollars.”

That savings in time directly influences the reduction in non-productive time. By identifying potential stress points discovered in video footage provided by RDI Technologies’ equipment, issues can be addressed before they fester into downtime. By reducing that non-productive time, RDI Technologies directly touches the safety and carbon footprint factors.

Motion Amplification® technology reduces the number of times equipment must be touched and handled. By reducing the number of touches, energy consumption is saved. With no spill to cleanup or incident to manage, energy exerted by response machinery and equipment is lessened. An increase in safety parallels the reduction in energy. By eliminating corrective action to failure, the potential of someone succumbing to injury or death decreases exponentially.

The oil and gas industry sees additional benefits in safety when deploying Motion Amplification® technology. While it curbs contact with potential hazardous outcomes, using the technology itself is conducted in an extremely safe fashion.

“Safety is of paramount importance,” says Barna. “Our technology offers the ability to collect data through non-contact methods. The user does not have to physically touch the equipment in any way.”

While many ideas seem plausible on the forefront, but fail to meet specific standards associated with the oil and gas industries, RDI Technologies worked within the industry’s parameters to develop technology usable without limitations. Because Motion Amplification® eliminates physical touch, distance becomes an ally when engaging the technology. No physical sensors must be placed on what is to be surveyed, so no need arises for the user to be in close proximity to the object being videoed. Spectacular lenses with great distance capabilities close the gap between the user and what is to be evaluated.

With the ability to perform at significant distances, Motion Amplification® assists the user in operating under strict guidelines that potentially increase difficulty when gathering the needed data. Plants, booster stations and compressor stations typically restrict close access with potential ignition sources. Specific requirements govern how close one can approach live equipment with cameras and other equipment that may not be intrinsically safe. RDI Technologies and its Motion Amplification® removes the guesswork and risk with its ability to record and capture video footage at safe distances from the objects in view. This even eliminates the need for permitting in some situations as a safe distance outside of the plant can actually be maintained. No matter the distance, RDI Technologies engrained image stabilization to manage camera shake.

Hydraulic fracturing carries significant levels of pressure. Those areas are identified as high-pressure zones, which carry restricted access during pumping procedures. When those extensive levels of pressure are carried for extended periods during fracking, vibration would be at its highest. While it might seem impossible to collect the needed footage during these pumping operations, Motion Amplification® technology can be deployed at a safe distance away from high pressure zones and still provide the data needed.

Investing in the Future

Cost drives earnings within the oil and gas industry and RDI Technologies stands ready to meet customer needs in this area and others. An increase in production increases overall profit and is made possible through well optimization and the acquisition of additional assets. In both categories, RDI Technologies can assist customers during the pre-purchase process.

Wells that receive stimulation and optimization reflect an increase in production, which yields an increase in flow. Increasing flow rates can increase vibration and lead to potential failure. Motion Amplification® can be used to study the impact increased flow rates have on pipelines and process equipment. Data collected and then interpreted can influence just how much of an increase can be managed safely.

Motion Amplification® provides an excellent opportunity in assessing future assets to be purchased. Video footage can reflect just how many potential fail points are possible. Because of data captured in video, the potential buyer may be able to see risks not noticeable by just looking, studying and viewing equipment in real time scenarios with only their eyes and no mechanical assistance.

Technology has historically been used in the oil and gas industry to better the end results. With RDI Technologies’ capabilities to improve data collection, it will continue to benefit the industry as it evolves and is led by a younger generation stepping forward.

“Our technology appeals to the new people coming into the industry,” says Barna. “The young people love it.”

As in any business, the newcomers and technological advancement drive improvement. This has always been the case in the oil and gas industry. Horizontal drilling, hydraulic fracturing and even well stimulation methods serve as examples of improvement just as Motion Amplification® does today. RDI Technologies’ ability to use cameras and software to gather critical data safely and efficiently captures the very spirit of making the oil and gas industry better for years to come by increasing profits, decreasing carbon exposure, and improving the safety of those pioneering the industry.

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.