Electromagnetic (EM) waves/fields from lightning strikes constitute indisputable scientific fact. They are a major cause of electric power outages and are the basis of national lightning detection networks. The issue of the EM effects of lightning has been central in areas like the electric power industry since the 1950s; however, by 2023, it has yet to be meaningfully introduced into lightning protection standards serving the petrochemical industry.

The video that captured the lightning strike that caused the June 3, 2023, fire in Lake Charles, Louisiana, may be instructive. A large steel tank was struck on the handrail. If the threat posed is strictly related to lightning currents as described in NFPA 780 and API 545, it’s hard to see how the fire could have started. If, however, one considers that lightning also produces enormous EM fields/waves, suddenly we can see that the tank possesses much vulnerability. This analysis is expressed in a video by Lightning Electrotechnologies.

Lightning Rods Are Not the Answer to Everything

Storage tanks that contain flammable vapor and electronic equipment have something in common: Both can suffer catastrophic damage from a small spark.

Electronic circuits can be sensitive to the EM effects of lightning. Inducing potentials can produce radio interference or they can physically damage components. The solution is not to provide a zone of protection with lightning rods but rather to provide means of EM shielding – enclosures that restrict damaging EM waves/fields from reaching sensitive components. This technique is effective against all kinds of EM interference. This is one reason that many electronic devices are in metal enclosures, both to protect them from incoming EM signals and to prevent them from radiating EM signals.

Protecting structures like storage tanks that contain flammable vapor or their vapor leaking components with lightning rods does not address the threat from EM effects. Furthermore, if struck, the protection system itself can become the source of hazardous EM fields.

Grounding Does Not Prevent Sparking

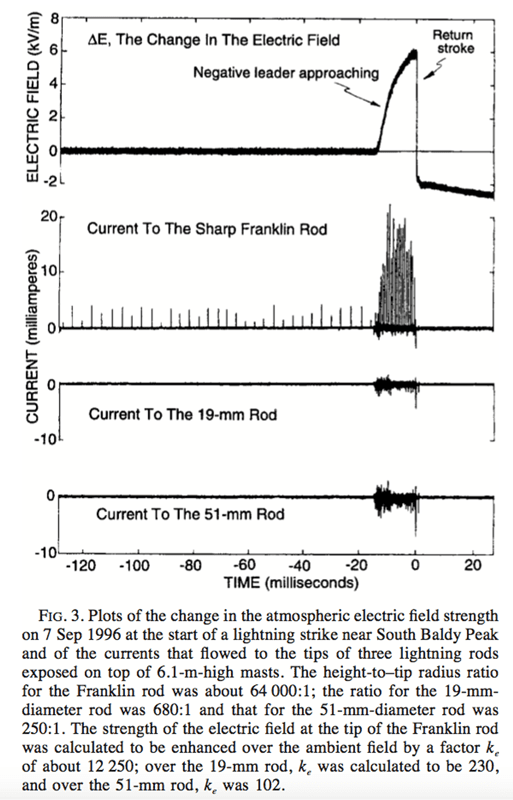

This figure, from a paper referenced in NFPA 780, “Lightning Rod Improvement Studies,” by Moore, et al., shows the electric field produced by a lightning strike and the sparking measured from grounded lightning rods within two kilometers of the strike. This demonstrates that radiated fields from lightning strikes can remotely induce sparking at great distances, that grounding does not prevent such sparking, and that gaps are not required for lightning-related sparking to occur.

Had the lightning rods in Moore’s paper been pipes emanating from a storage tank or similar, sparking of sufficient energy to ignite flammable vapor could have been induced onto the edges of those pipes.

We believe that this is how the majority of lightning related fires at petrochemical facilities start and protecting such grounded pipes/vents and storage tanks with lightning rods, further grounding and bonding as recommended by NFPA 780/API 545, would have no beneficial effect in preventing such fires.

An NFPA-appointed task group in March determined that the technical committee responsible for tanks lacked expertise in this area; however, the NFPA Standards Council decided to take no action.

Hazardous Recommendations In NFPA 780

On October 27, 2022, the most respected and authoritative body of lightning protection experts in the world, the Scientific Committee of the International Conference on Lightning Protection (ICLP) issued a statement calling for the removal of a section of NFPA 780. The section, which recommends placing corona-generating devices (long conductors with sharp points or similar) inside nonmetallic tanks, was deemed potentially hazardous in the event of direct or indirect lightning strikes.

The hazardous recommendation in the NFPA standard is not supported by any peer-reviewed scientific papers, laboratory or field-testing. The only reference provided is to another NFPA standard, NFPA 77 (Static Electricity). Curiously, however, NFPA 77 identifies corona discharges as hazardous in environments with flammable gases and NFPA 780 recommends putting corona-generating devices inside tanks that contain flammable vapor, and cites NFPA 77!

This video expresses the view that NFPA 780 can increase the risk of damage.

Incorrect Information in API 545

The following is a description of indirect lightning strikes from API 545 and which omits any reference to EM effects:

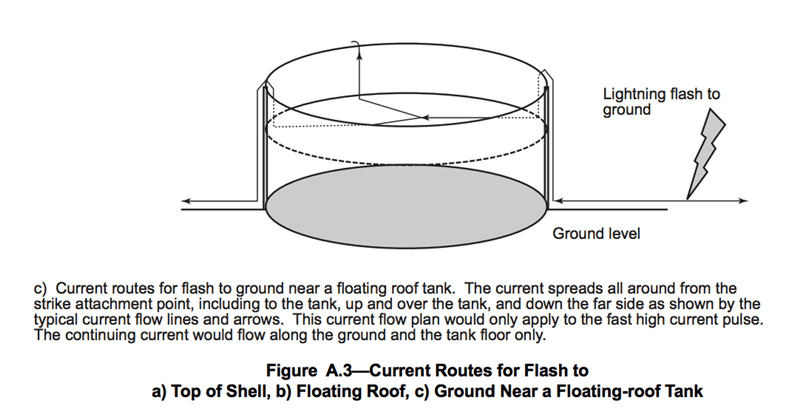

“A.1.4.3 Effects of Indirect Lightning Strokes

For a stroke adjacent to a tank, some current will flow over the outer skin of the shell across the fixed or floating roof and down to the ground on the other side of the shell (see Figure A.3 c). There would be much less energy in the discharge currents moving across the tank as compared to a tank directly struck. As with direct strokes, any discontinuities in the current paths may result in arcing across the gaps.”

Below is Figure A.3.c from API 545.

Only figure c) is presented. Figure a) Top of Shell, and b) Floating Roof are not presented.

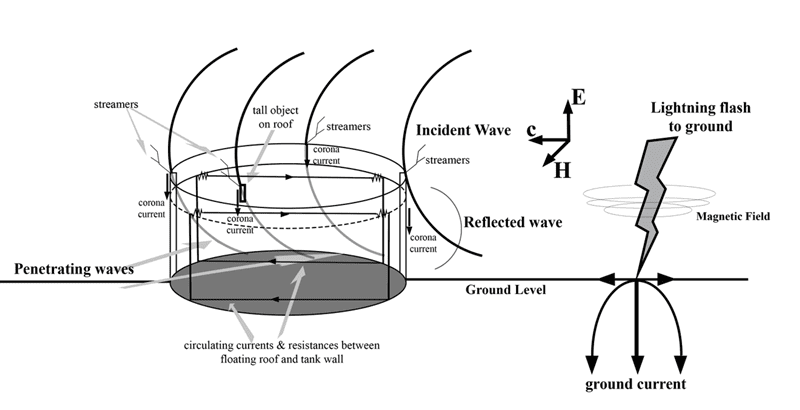

A view which does take EM effects into consideration may appear as follows:

When lightning terminates to ground, the current will mainly penetrate the ground at the location of the strike with only a minor proportion flowing on the surface within a comparatively small region depending on ground resistivity. The return stroke current will create a magnetic field around it and an associated electric field component generally perpendicular to the ground plane. Such an electromagnetic wave will flow far away from the strike point.

When lightning terminates to ground, the current will mainly penetrate the ground at the location of the strike with only a minor proportion flowing on the surface within a comparatively small region depending on ground resistivity. The return stroke current will create a magnetic field around it and an associated electric field component generally perpendicular to the ground plane. Such an electromagnetic wave will flow far away from the strike point.

If such a wave strikes a metallic object, like an EFRT, the situation can be visualized as follows: The incident wave will be scattered and a penetrating component will flow through the metallic wall. The magnetic field will create a circulating current that will result in a reduced but non-zero field inside the tank. The electric field will create induced fields and space potentials at the edges of the tank and along the roof that could result in sparking. Sparking from grounded or electrically floating metallic objects could constitute a hazard where flammable vapors are present.

Given the incorrect view expressed in API 545, the recommendations are limited to questionable methods of bonding between the floating roof and tank shell with no consideration for any EM effects. These same recommendations and omissions appear in Chapter 7 of NFPA 780.

What Does EM Shielding for Storage Tanks Look Like?

Non-conducting tanks that contain flammable vapor are particularly vulnerable to EM effects. This is because non-conducting materials like fiberglass are easily penetrated by EM fields/waves. These penetrating fields can therefore induce sparking onto metallic components inside the non-conducting tank. The only way to protect a non-conducting tank is to provide it with means of EM shielding, like the EM Shield by Lightning Electrotechnologies.

A study of 20 sites in an area of high lightning activity found that between 2018 and 2021 on 271 occasions a storm cell was within one kilometer of a site protected with EM Shields and no damage was reported. To date, no lightning related damage has been reported, but no update on lightning activity is available.

Please contact us for information about EM shielding for fiberglass tanks, steel tank components and EFRTs at info@lightningelectro.com or 514-983-3365.

Amir Rizk, B.Sc., Physics, MBA. Manager of Lightning Electrotechnologies, Inc., Rizk is a contributor to the world-renowned research in the physics of lightning, lightning protection, and high voltage engineering by Lightning Electrotechnologies, Inc., and its founder, Dr. F.A.M. Rizk, and has appeared on a number of their scientific publications and five U.S. patents.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.