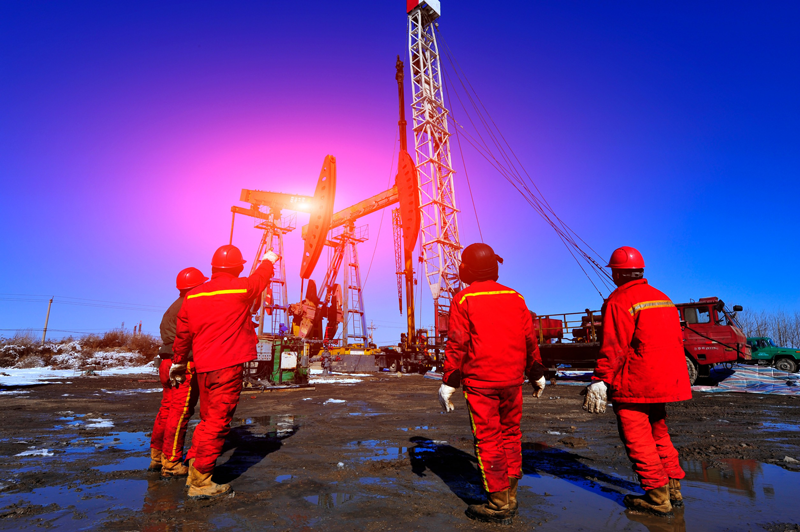

The oil industry is profitable, but it often comes with losses. Oil workers handle flammable chemicals and gasses while dealing with operations that pose a risk of fire accidents.

In high-risk industries like the energy industry, it is essential to have fire prevention measures. Preventing fire in the oil industry is crucial for the worker’s safety, the property and the environment. Preventive measures are also in compliance with OSHA regulations aimed at mitigating hazards.

What follows is a comprehensive guide to preventing fires in the oil industry and maintaining a safe working environment.

Learn about other threats facing the oil industry in this blog.

Three Benefits of Worker Safety in the Oil Industry

The safety of workers in the energy industry is of great concern. The high-risk environment puts them at risk of fires, explosions and poisonous gas leaks.

Thus, the CDC reports the death rate in the oil industry is seven times higher than in other industries. However, understanding the importance of worker safety can help reduce these numbers. Every oil company should strive to provide worker safety for the following reasons.

1. Preservation of Life

The priority for safety should be the preservation of human life. The oil industry is volatile, and a safety failure could result in the tragic loss of lives. For instance, the 1988 Piper Alpha explosion was one of the most catastrophic accidents.

A massive explosion from a gas leak resulted in the loss of 167 lives, most of whom were workers. Minimizing the risk of accidents is key to saving the lives of workers.

2. Boost Employee Morale

A secure and hazard-free workplace enhances productivity and efficiency. When you implement safety protocols, your employees feel secure, gain confidence and have a boost in morale.

Consequently, they focus more on their tasks, decreasing absenteeism and turnover, and increasing job satisfaction. Furthermore, a company that cares for its workers has a great reputation in the public eye.

3. Compliance with Regulations

It is the ethical responsibility of a company to safeguard its workers. Besides ethics, oil companies are legally required to provide a safe working environment. OSHA has stipulated fire and explosion regulations for companies to meet.

Failure to comply with these regulations could result in legal consequences and damage your reputation. Implementing worker safety measures helps the oil industry comply with regulations and prevent accidents.

What are the Common Causes of Fires in the Oil Industry?

The oil industry is prone to accidental fires as oil and its byproducts are extremely flammable. According to the National Fire Protection Association, municipal U.S. fire departments reported around 37,910 industrial fires costing up to $1.2 billion in property damage.

While some causes of fires are natural and accidental, others result from human error. Below are the common causes of oil industry fires.

1. Damaged Equipment

Faulty equipment such as compressors, pumps and pressure vessels can overheat or have leaks, resulting in fire. Old equipment that doesn’t perform optimally can also lead to accidents, including explosions. However, even new equipment can be substandard or poorly designed and cause accidents. To ensure the safety of your workers, have your equipment maintained.

2. Electrical Fires

Damaged electrical wires can cause sparks that result in fire. Companies should have strong electrical systems to prevent ignition. It is crucial to identify ignition sources like naked wires and insulate them to prevent fires.

3. Poor Handling of Gas

Improper knowledge of handling gases can result in devastating fire losses. Workers must be aware of fire risks, like smoking cigarettes in the presence of flammable gasses. Employee training can reduce the risk of fire accidents.

4. Transportation

The oil and gas industry involves transportation, posing a significant risk of fire and explosion. Different modes of transportation, such as pipelines, ships, tankers and trucks, are used to transport these products. However, road accidents, oil leaks and spills during transportation can lead to severe fires and explosions, causing fatalities.

Ways to Implement Effective Fire Safety Training Programs for Workers

Fire accidents can cause devastating losses of property and lives. Fortunately, implementing fire safety training programs for workers can minimize the risks. Furthermore, companies are required by law to offer fire safety training to their employees as per the standards set by the Occupational Safety and Health Administration (OSHA).

Training your employees should involve preventing and responding to fire accidents. What effective steps can you take to create a safety training program?

Encourage the Use of Proper PPE

An important step toward safety in an oil company is educating your workers on the role of personal protective equipment. PPE prevents direct contact with and inhalation of toxic substances. Flame-resistant PPE is effective in protecting against burns during a fire.

Nonetheless, PPE should be properly fitted to ensure maximum protection. Therefore, women should wear female-designed PPE specifically made to fit women’s bodies and enhance comfort, movement and safety.

Train on Evacuation and Emergency Procedures

Evacuation plans are essential to creating safety awareness during fires. Ensure all workers understand their responsibilities and action plans during evacuation. The evacuation plan should include exit routes and a designated assembly area. Additionally, a comprehensive first aid training that includes performing cardiopulmonary resuscitation (CPR) and proper use of Automated External Defibrillator, or AED, is necessary to help during emergencies.

Perform Fire Drills

Fire drills are an essential part of fire safety training programs. They are ideal for determining whether your employees understand the evacuation plan. The drills should be routine (at least monthly) to increase response time. The drill should also include checking the performance of the fire extinguishers.

Train Workers to Identify Fire Hazards

Offer training on identifying fire hazards as a preventive measure. Additionally, train workers to conduct fire risk assessments and remove fire hazards in the workplace. Offer a safe smoking area and educate them on the importance of discarding cigarettes safely to prevent ignition.

Preventing Future Incidents: Safety Culture and Continuous Improvement

It is important to have confidence in handling fires and other emergencies. Safety culture is a crucial aspect of preventing fire accidents in the oil industry. It is the collective attitude, beliefs, values and behaviors regarding safety within an organization. Ensure that you adopt a culture of continuous improvement as you upgrade your technology and practices. The following are additional tips to help prevent fires in the future.

Conducting Inspections

Conducting regular audits and inspections of equipment can help prevent future accidents. Focus on inspecting areas particularly susceptible to fires and explosions, and develop a plan of action if you find any faulty equipment. Routine inspections offer peace of mind to you and your workers.

Fire Prevention Procedures

Develop and enforce stringent fire prevention procedures tailored to your organization’s fire risks. This includes proper storage and handling of flammable materials. Ensure equipment maintenance to prevent leaks or malfunctions that could lead to fires.

Install a System to Monitor Gas Leaks

Oil industries may have dangerous gas leaks that are combustible. Unfortunately, negligence in controlling gas leaks can result in fires. Install a system to detect gas levels and alert your system when they reach dangerous concentrations.

Reaping the Rewards

Companies and workers alike can reap major rewards from a focus on worker safety. Preventing oil industry fires is crucial for worker safety, asset protection and environmental protection.

To protect themselves from potential legal consequences and reputational damage, businesses must ensure they are in compliance with safety regulations. They must encourage proper personal protective equipment (PPE), train on evacuation procedures, conduct regular fire drills, and empower workers to identify fire hazards to create a safety-conscious workforce.

Steven John Cumper, B.App.Sc. (Osteo.), M.Ost., is a businessman with a strong background in biomedical science and osteopathic medicine. He founded Medshop while studying at RMIT University in Australia, expanding its reach to markets in Papua New Guinea, Singapore and Malaysia. In September 2021, the Bunzl Group acquired a majority stake in Medshop, but Cumper remains involved as the Managing Director (Medshop Group). His journey from Zimbabwe to the U.K. and Australia reflects his dedication to academia and entrepreneurship, combining diverse knowledge and experience.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.