Energy efficiently applied is the future of a globally fractured oil and gas market. Menial labor cannot be a factor in future business equations as companies must consider pure energy costs from a human capital standpoint. The genesis of solving that problem is implementing an affordable, automated supply chain platform that provides accurate and granular consumption data, a magical user interface, and collaboration among manufacturers, suppliers and consumers.

Automation conversations of the past centered around technology replacing people. Instead, companies are finding ways to augment the people they have and find a more efficient way to apply labor.

One thing is certain: Any supply chain solution must hold a win for the supplier and a win for the consumer. The systems that can provide a return on investment for both will propel the oil and gas industry into a more efficient future.

Current Oil and Gas Supply Chain Challenges

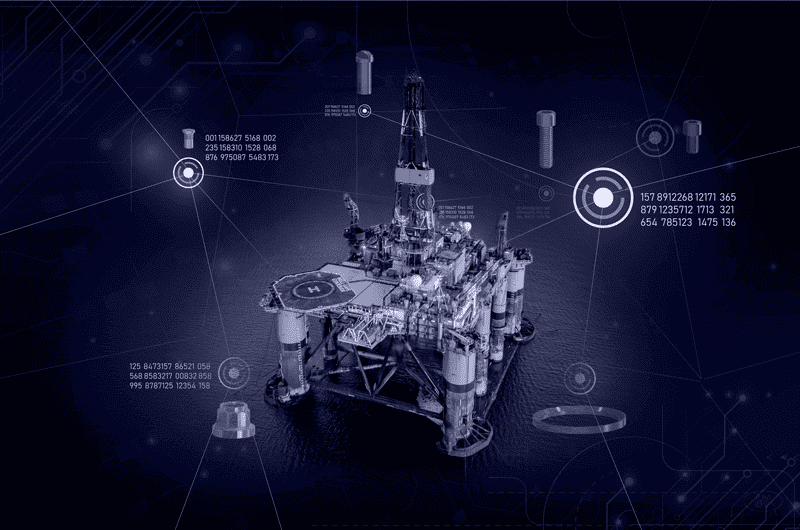

The remote aspect of upstream oil and gas operations combined with the crucial need for traceability are some of the biggest challenges facing the industry’s supply chain.

Traceability

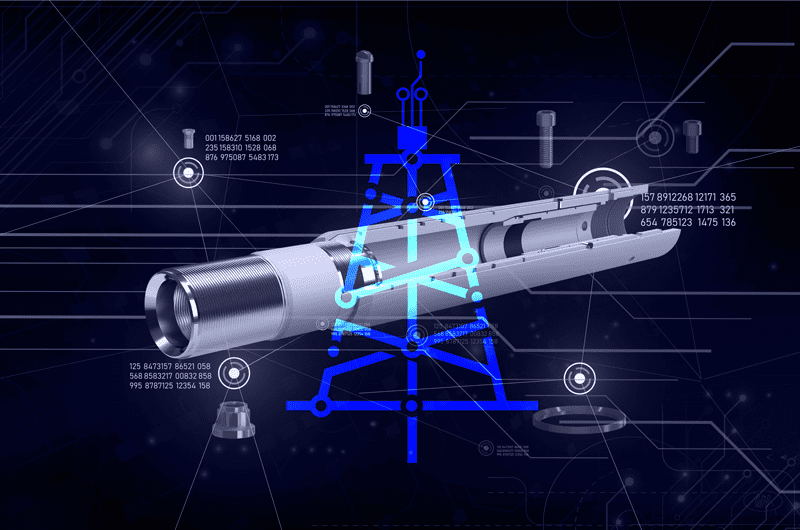

The oil and gas industry needs better traceability from a supply chain standpoint, from the product provider all the way to the point of installation. Digitization will help to improve this challenge by providing traceability throughout all the supply chain partners, particularly when they are all on the same platform.

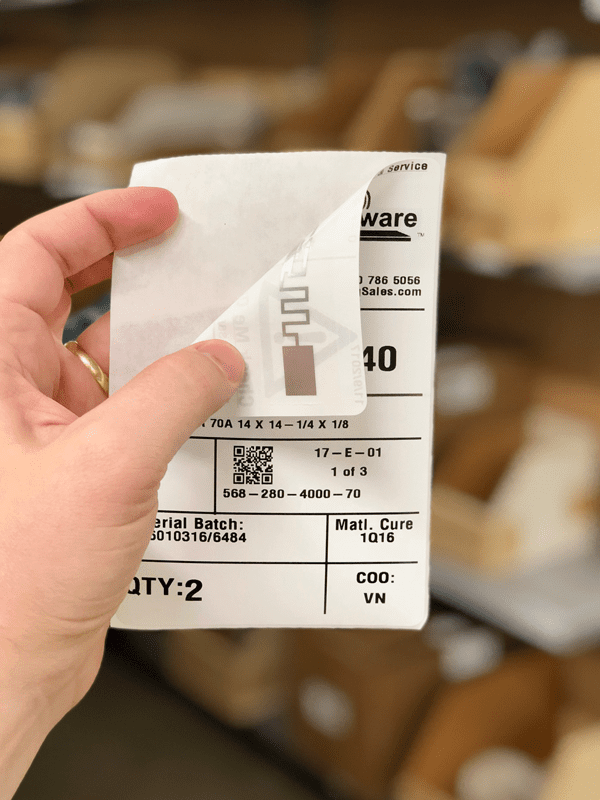

There is an enormous volume of reporting mandated for the oil and gas industry, and compliance of API standards requires traceability. However, many manufacturers currently accomplish this with a cumbersome paper trail handoff between various points of the supply chain, a process that is labor intensive and prone to human errors.

With a digital vendor managed inventory (VMI) system, the data can be pushed into a digital platform, handed off digitally to the supplier, and then trigger that handoff when the product is pulled from the inventory. When the part is physically removed from the inventory, the product is tied to the digital paper trail and targeted to be deposited into the manufacturer’s quality control or compliance digital file tree so that it can be easily and accurately referenced.

“If equipment components are purchased from a manufacturer who has full traceability all the way down to where the steel was cast, based on serialization of the parts stamped onto the heads of the bolts, we can then identify who manufactured the parts, what process was used, what heat treat lot it came from, the type of forging, the type of machining, the test sample the bolt came from, and the results of those tests,” says Scott Cunningham, sales manager at WN Global, a bolting manufacturer for the petroleum and natural gas industries. “Using an RFID tag, all that information can be embedded for quick reference and traceability. A digital VMI system is automatic and customizable.”

Remote Aspect of Oil and Gas Marketplaces

Upstream oil and gas companies often work in extremely remote places with minimal infrastructure. The consumer of the industrial product being supplied could be 300 to 500 miles away from the closest supplier. The remote aspect of drilling operations often affects sustainability, fuel efficiency, fuel prices and labor prices. It makes managing that remotely-deployed inventory extremely expensive and time consuming.

The traditional model of VMI relies on branches being closer to service areas. In most upstream oil and gas operations, that’s not possible. With an internet-based technology, the data on what’s being consumed at the job site is virtually transmitted with real-time visibility.

“A lot of the products we are talking about are incredibly long lead-time products,” Cunningham explains. “They are not off the shelf. They either must be manufactured or stocked somewhere close by, which is unlikely.”

Real-time usage inventory helps forecast future demand.

“When you consider some of the more critical oil field products, like specialized screws for high power-pressure drills, some of the screws are made from MP35N (an incredibly hard to find and hard to machine part, considered a precious metal),” Cunningham explains. “They are not going to keep 500 of those on the shelf at around $175 each. And they don’t know they need them until they break. So, they may keep 10 on site, but they will need a backup supply somewhere. A digital system that can trigger usage and can also trigger replenishment.”

The downtime repercussions of critical component stockouts on a drilling site can cost hundreds of thousands of dollars per day.

“A drilling environment is harsh,” Cunningham says. “I’ve seen drill bits that are four inches in diameter and made of solid steel completely twist and break due to the enormous drilling pressure. When that happens, they must retrieve the broken bit, find out what’s been broken specifically, all while 200 to 300 people are just standing around. It doesn’t take long to add up to huge amounts of money. They need that new part right now.”

Solving Supply Chain Challenges with Digitalization

It is common to paint a grandiose picture of digital transformation, but almost all change management is incremental. What’s unique about a sophisticated digital VMI platform is that it’s a practical enough digital solution to be applied to existing companies, existing supply chains, and existing infrastructure without massive upgrades.

Once applied, digital VMI is practical and flexible. With this foundation, the digital transformation process can be started. Features like traceability and collaboration among suppliers are built in. The transformative power is made possible by taking that first step into automation, establishing the underpinning granular, fine consumption data. Once the foundation is set, companies can build on it over the course of months and years. Technological innovation becomes a marathon that is run in a series of sprints.

Cunningham is no novice when it comes to managing supply chains. Beginning with Fastenal in 1986, he has nearly 40 years of experience and has seen an evolution in which all solutions lead to digitization.

“There are a billion different ways to manage inventory,” he explains. “Some companies just send a guy out to check the bins and fill them up as necessary, which is an antiquated method. There’s never been a great solution that provides real-time inventory data and real-time consumption data that is so easy to use. A platform like ShelfAware, that uses RFID smart tags rather than barcodes, provides the ability to take the scan gun, log into the inventory room, and hit one button. You get the dollar value of the entire inventory, line by line, with just the push of that one button. I know how many XYZ bolts I have and their value. I can even tell how much my inventory room is worth, which is great for insurance purposes.”

“The real-time consumption data is critical for high-consumption fasteners. It’s mind blowing. In a traditional bin-stock system, where you have bins full of fasteners, to determine the value of the inventory you have to physically count every piece of hardware, go back to the books, and find out how much you paid for it. Inventory can become a highly involved math equation that could take a whole week to solve. With ShelfAware, as long as it’s scanned, each piece is recorded along with all the appropriate data.”

The package level scanning allows flexibility with customizable data consumption. If you want to track one bolt at a time because it’s expensive or because it’s critical, you can. But you can also track one thousand bolts at a time.

In addition, digital VMI systems allow collaboration with other highly technical, vertically integrated suppliers of various parts through the power of CloudSourcingTM. This omnichannel platform accommodates both the physical (inventory: logistics, storage, tracking consumption, organizing, etc.) and the digital (data: analytics, forecasts, replenishment metrics, etc.) aspects of complex supply chains.

“The ability to partner with other companies – for instance, lubricant or seal suppliers – provides collaborative partnerships that make it possible to put an onsite person in place in these remote locations,” Cunningham says. “It’s a huge value to the customer because they have the products when they need it and where they need it. Digitizing the entire supply chain for all original equipment manufacturers allows us to capture the spend and apply it to a specific job number, based on the parts we pull for a particular job. There are a multitude of ways to customize it. Now, you can get a true amount of what it costs to repair a specific drill bit for a specific job, tracking a true and specific ROI for individual jobs and job sites.”

When pulling products from inventory, various pieces with RFID smart tags can be placed into a tub and then placed on the ShelfAware scanning table. It can be programmed to require a job number. When analyzing the data, future forecasting of inventory consumption can be determined for each specific job or job site. The data dashboard can be accessed at any time.

Automation removes unnecessary steps from the supply chain process.

“With a robust digitized system like ShelfAware, as soon as a piece of inventory is low, delivery of new products is immediately set in motion,” Cunningham says. “This is tremendously valuable for suppliers and consumers. Triggers are set in place. For example, if a customer wants to keep 1,000 of a certain bolt in inventory, there is a trigger when the inventory reaches 700. It’s automatic. It frees up the purchaser, the receiver, the transportation, and creates a win-win for everyone.”

Headline photo: The remote aspect of upstream oil and gas operations combined with the crucial need for traceability are some of the biggest challenges facing the industry’s supply chain. Image courtesy of WN-Global.

Andrew Johnson is an entrepreneur, inventor and business owner. Formerly the sales manager at the family distribution company, he is now the CEO of ShelfAware, which is redefining industrial supply chains by leveraging RFID technology, the internet and the power of data. He can be reached at andrew@shelfawarevmi.com or (913) 270-8400.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.

1 comment

Comments are closed.