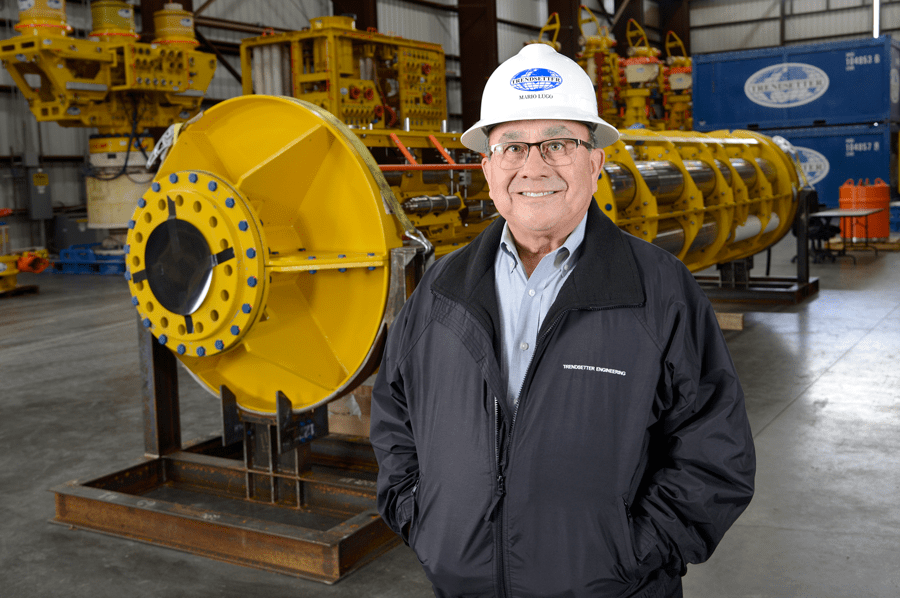

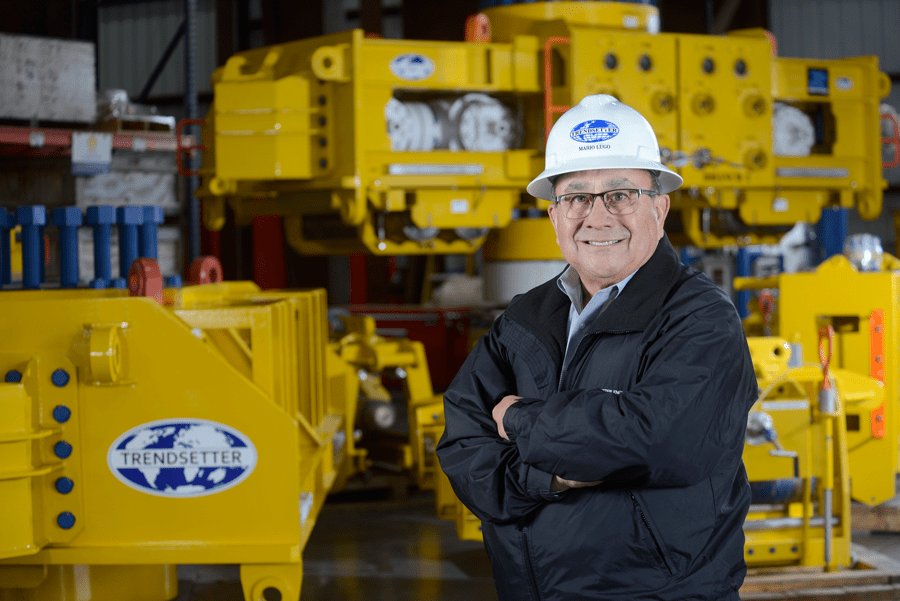

Mario Lugo, P.E., has a prediction to make: “The offshore industry as a whole will still be slow in 2022, but I believe there will be increased activity in the Gulf of Mexico (GOM) and a few other areas,” despite tightened BSEE regulations and the intense capital requirements to develop deepwater projects. Lugo, founder and CEO of Trendsetter Engineering, Inc., a provider of specialized subsea solutions, says oil companies have modified their primary strategy from production growth to growing investment return. He points out that deepwater projects are extremely expensive, and typically require additional time to plan and sanction, while noting that U.S. GOM rig utilization is up this year compared to last year – indicating more operators are spending money exploring and developing projects. Lugo adds that the current price of oil helps “push a number of projects across the line.”

“Major operators did sanction projects in the last few years and their focus will be on executing those projects and overall return on capital,” Lugo, says, citing bp’s Mad Dog project and Chevron’s Anchor project. “We have seen the smaller independent operators react quickly to the increased commodity prices and develop infrastructure-led exploration (ILX) prospects with smaller subsea tiebacks that can be developed quickly.”

Independents Up Their Game

With many of the majors selling their offshore interests and/or assets, Lugo sees more independents entering the offshore exploration and production (E&P) arena, something he says is a worldwide trend. However, Trendsetter’s recent focus has been in the GOM, which Lugo says, “Offers a very unique, but proven, arena for these smaller operators to enter the market. The GOM and its infrastructure tend to allow these smaller operators to execute projects much more quickly, enabling them to balance the cash flow and return on capital.”

This trend definitely impacts Trendsetter – in a positive way. “We believe that Trendsetter is key to these independents and their business model,” Lugo says. “These companies are looking for us to respond quickly without compromising the quality they require to safely develop these fields, which we have proven to do successfully in the past. Most notably, we recently supplied our subsea connectors to Murphy’s King’s Quay project and LLOG Exploration Offshore, LLC, and are currently working with BHP to supply its subsea production system, including our innovative HIPPS to the Shenzi North Project.” Outside of Trendsetter’s subsea production systems, it has supported independents with its well intervention systems and BOP tethering systems.

The GOM Heats Up

The offshore landscape is changing with major decommissioning projects underway in the U.K. and a greater focus on offshore wind in Norway; however, Lugo believes the GOM will be a hot spot for E&P offshore activity. With its existing infrastructure and proven reservoirs, the area is a lower risk basin. In addition, it is noted worldwide as having lower carbon footprint production.

In the U.K. and the North Sea area, Lugo says significant activity has been seen where majors are being replaced with independents. “It remains to be seen how active the independents will be in that area. However, we have seen a demand in well intervention and interest in our Trident intervention system to support that area.”

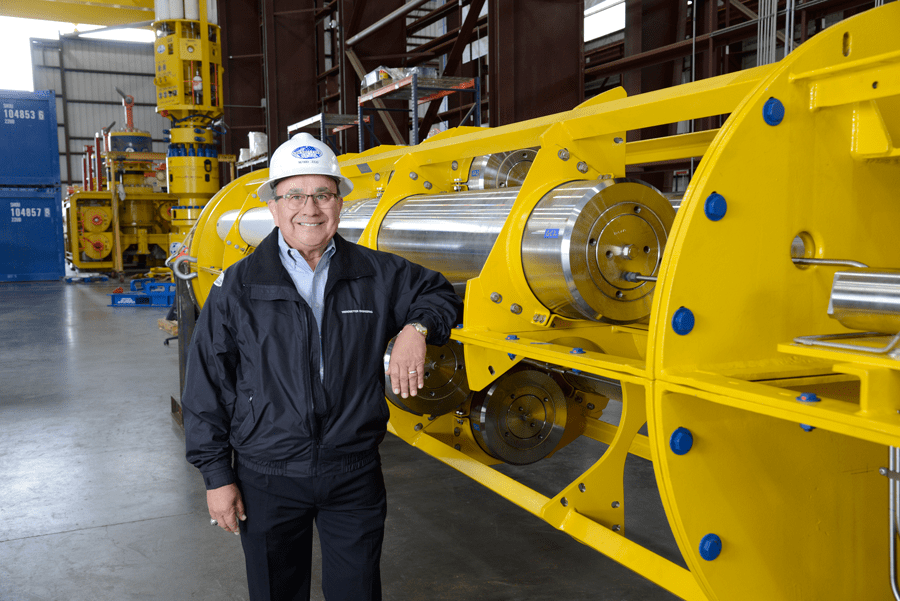

Capping Stack in Record Time

Having been in the industry 50 years, Lugo has witnessed firsthand some of the catastrophic accidents that have occurred offshore; however, Trendsetter has managed to achieve over 1,000,000 consecutive hours without a recordable incident, in part because of the company’s specialized offshore emergency response.

When Lugo established Trendsetter in 1996, it was with the express purpose of finding the best people to support the growing subsea industry. “This philosophy continues today,” Lugo says, “and is reflected in our safety record and the equipment we deliver.”

When the Macondo incident occurred, ExxonMobil, with whom Lugo was contracted, asked him to lead a small team to help bp in any way we could. Simultaneously, Trendsetter was asked by MWCC (a consortium made up by ExxonMobil, bp, Shell, Conoco Phillip and Chevron) to build an interim capping stack because the permanent capping stack it had already ordered was going to require years to build. “We quickly accepted the challenge,” Lugo says, “and were able to place orders immediately for the valves and forgings from our friends at Advanced Technology Valves (ATV) in Italy and other industry partners.”

Crediting the “exceptional Trendsetter team” and reliable supply chain in Houston, Trendsetter was able to completely design and build the capping stack in a record seven and a half weeks. This was a huge achievement, Lugo notes, as this interim capping stack allowed the Obama Administration to reopen offshore oilfield operations for the major operators in the GOM after the industry had been shut down for almost a year.

Afterwards, HWCG, another consortium of operators, requested an additional capping stack which was completed in six and a half weeks. Other capping stacks and specialized emergency response equipment for Shell and Oil Spill Response Limited (OSRL) followed. “The industry really came through for us,” Lugo says.

After the initial push for capping hardware, Trendsetter started to develop additional hardware to round out the emergency response toolkit. This included developing a cap and flow system for worldwide use, its patented RWIS system to facilitate rapid well kill operations and, most notably, its 20K, High Pressure/High Temperature (HPHT) equipment.

“It is also important to educate the general public to see the benefits of the oil and gas industry and the actions we take to ensure another Macondo event never happens again,” Lugo says with conviction.

Spotlight on Environment, Social and Governance

“ESG is an interesting topic for Trendsetter and for me specifically,” Lugo says. “Goals for ESG can be very broad and, ultimately, not very useful if not adopted in a conscientious manner. I am a conservationist at heart and try to ensure that Trendsetter follows suit.” The company bought acreage in Houston around the Trendsetter facility in order to increase the size of its campus – only to discover that one acre had an illegal dump on it. “I volunteered to clean it up for the State of Texas,” Lugo says, “and it ended up costing the company more than 30 times my original cost.” Nevertheless, “We do the right thing at Trendsetter.”

“We feel we are doing our part to help promote a cleaner oil and gas industry.” Not only does Trendsetter invest in and maintain the oil spill response equipment to protect the oceans, but it also does small things at the Trendsetter facility, even changing high bay lights to LED to conserve power. The company has consolidated operations on its campus to reduce the trucking required to deliver equipment.

“Also, we review every design to see if we can reduce the weight of the structure; ultimately, this saves steel and the labor to process the steel and finish the design. The true cost of overdesigning product can be staggering,” Lugo says. “All of these stages add up to a massive carbon footprint. Our job as suppliers and engineers is to deliver to our customer the best, most reliable equipment with the least cost, all while meeting the requirements, as well as the protecting our natural resources.”

“I tell engineers, ‘You’re not finished with a project until you pull it out of the water 30 years later.’ We think about those long-term ramifications.”

Looking forward, Lugo says Trendsetter is investigating the equipment and technology needed to support the growing carbon capture industry.

Family and Community Culture

Trendsetter is a family operated company with his twin daughters, Natalie Older and Nicole Downing, and their spouses, David Older and Ron Downing, working actively in the company. “It is a blessing to work with my family and I am proud of Trendsetter’s legacy.” Lugo says employees are considered part of that family. “I believe in transparency with our employees. When times are tough, we talk to our employees and try our best to keep our team intact.” It’s that mindset of being in it together for the long haul that helped Trendsetter avoid layoffs during the ongoing pandemic.

By the same token, Lugo says, “When times are good, we celebrate with the employees, so that they know they are appreciated for their talents.” Special activities and events represent the family-oriented mindset that extends to the company’s customers and vendors – many of whom have been with Trendsetter from the beginning. “This mentality applies to our safety culture as well. We want everyone to contribute and go home safely knowing that they were instrumental in delivering the project.”

Lugo is a strong supporter of community outreach, as well. Trendsetter participates in the Salvation Army Angel Tree program every Christmas and donates to local Houston-area schools, a passionate cause not only for Lugo, but also to his wife Alma, a former teacher. Lugo and company representatives host college kids and teach them what to expect once they graduate from college. But they start even earlier than that, speaking to fifth and sixth graders in inner city schools about the importance of a good education – the significance of which cannot be overstated. “Obviously, with my background, education was key,” Lugo says. “Engineering was the only thing that saved me.”

An Entrepreneur is Born

Lugo was born in Laredo, Texas, and grew up with three older siblings in a modest home. In high school, he was strong in the areas of math and physics and enjoyed solving complex problems and figuring out how things worked. He had a strong desire to achieve success and decided to build a career based on those skills. He was convinced that higher education was the first step in reaching his goals, even though no one in his family had graduated from college. He attended Texas A&I University in Kingsville, Texas, where he graduated with a degree in mechanical/civil engineering. While he acknowledges there have been many incidents, people and events that have influenced his life and work, he has always believed that, through hard work and determination, anything can be achieved. “I was born with an entrepreneurial spirit, never feared failure, and have always had a passion for tackling what appears to be the impossible.”

Lugo’s career began in drilling technology, where he was first exposed to the oil and gas industry. His interest in blowout protection (BOP) controls and drilling processes allowed him to develop state of the art equipment and expand deepwater drilling in the early 1970s. Later, he began to explore subsea production systems. He found it challenging to design and construct reliable equipment that functioned effectively for many years subsea. Simultaneously, he got involved with Boots Hanson, of Boots and Coots fame, and participated in multiple underwater blowout studies. Building on those experiences, he later designed tooling for Pat Campbell at Wild Well Control, which would help control the blowouts in Kuwait after the Gulf War. Additionally, he performed more joint industry studies with Neil Adams Firefighters on how to control subsea blowouts.

In 1983, along with a partner, Lugo founded Oil Industry Engineering, Inc., where they pioneered technology that has paved the way for the industry, changing the industry standard. A few years after selling Oil Industry Engineering, Lugo established Trendsetter Engineering, Inc. in 1996. Twenty-two years later, he says, “One of the reasons I’m still working is there are so many opportunities. We’re doing something good for humanity.”

Creative Solutions for a Better Future

As the energy transition progresses, most experts – Lugo among them – agree that oil and gas will be part of the mix for the foreseeable future.

“The world’s energy infrastructure heavily relies on oil and gas and there are considerable challenges with the current alternative energy market. We all remember – if only from pictures – the frozen wind turbines in Texas in 2021. The energy grid needs to be updated to cater to these energy sources that fluctuate when the wind isn’t blowing or when there is a cloudy day. Energy storage is a huge problem that needs to be addressed.”

Trendsetter has been investigating the alternative energy sector to see where the company best fits in the changing landscape. “We are currently looking at a few impactful technologies but, more immediately, we are looking at how we can support the offshore oil and gas market in its transition.” Electrification is one area where Lugo believes Trendsetter’s technologies can support the oil and gas market, as well as the offshore alternative energy market.

“As I mentioned, I am a conservationist. I ranch for wildlife and cattle in a holistic method. I follow what was written 90 years ago by the “Father of Modern Wildlife Management” Aldo Leopold. ‘The central thesis of game management is this: Game can be restored by creative use of the same tools which have heretofore destroyed it – axes, plow, fire and gun.’ I use cattle to improve the soil and therefore wildlife. I burn diesel in the dozer to improve the land by adding diversity to the ranch land for the benefit of all wildlife. I plant several hundred trees every year, too. I have true appreciation for nature as it is simply wonderful.”

“Perhaps we can use the same philosophy with regard to fossil fuels. Perhaps, with creative use, we can reduce the carbon footprint.”

Headline photo courtesy of Robert Allred www.allredphotography.com

Rebecca Ponton has been a journalist for 25+ years and is also a petroleum landman. Her book, Breaking the GAS Ceiling: Women in the Offshore Oil and Gas Industry (Modern History Press), was released in May 2019. For more info, go to www.breakingthegasceiling.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.