Oil and gas production facilities are faced with a growing number of challenges today related to supply chain shortages, lack of skilled labor, and concerns around environmental compliance and sustainability. To combat this, facilities are moving toward solutions that enhance operational efficiencies by using new technologies for remote site monitoring, enabling greater awareness of different conditions onsite, while at the same time reducing costs. A key new development in this trend is to deploy cameras at the edge that use Artificial Intelligence (AI) to analyze and collect insights from the field of sight.

The mainstreaming of AI technologies have spurred the transition toward further automation and digitization of oil field operations. With these advancements, the oversight of regulatory compliance, environmental safety issues and other operational efficiencies can be conducted remotely and automatically. Coupled with advances in video analytics and camera technology, the industry is moving away from the more traditional manpower-intensive approach at sites.

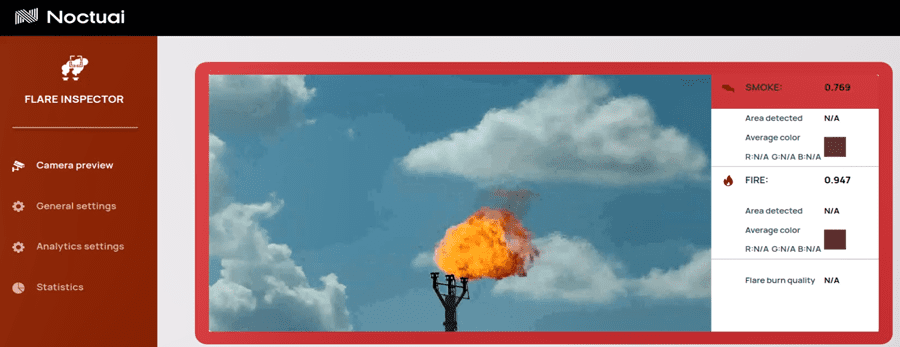

Existing technologies that have been used by energy organizations to monitor the presence of flares on oil derricks, levels of tank liquids, or the detection of gas leaks, have historically been singularly focused solutions. When AI analytics are coupled with new smart cameras, even a single camera at the edge of an oil field can perform multiple functions simultaneously. The secret sauce is to let cameras run multiple of these different breeds of apps that are trained by data scientists to perform specific functions. The applications can simply be called AI-apps.

AI-apps that run directly on the camera provide a cost-effective, yet flexible, alternative to traditional monitoring technologies. Unlike other existing solutions, AI-apps offer a high degree of automation allowing real-time alerts on potential issues and speeding up response to the issues, thereby helping reduce the frequency and expense of EPA and OSHA fines. The cameras with AI-apps also dramatically reduce video storage and bandwidth costs, as they are able to make intelligent autonomous decisions at the camera level about what video footage is relevant to save on-site or transmit to a central location.

Eliminate Environmental Violations and Fines

Oil and gas operations are under increasing pressure to be even more environmentally conscious and comply with an evolving slate of regulatory requirements. Operational mishaps can result not only in environmental detriments, but also in massive fines from the EPA. As such, automated monitoring can help to remain compliant with regulations by ensuring clean flaring, detecting high tank levels and gas leaks early, and reliably controlling remote onshore and offshore facilities.

So, how does it work? A smart camera equipped with smoke and flare detection will pan the facility, identify venting or smoking in gas flares when there is one, and notify the responsible team of the abnormality. The automation reduces the response time, which is mission critical for operators, as they can’t take chances on letting abnormalities in flaring go undetected.

Gas leak events are notoriously hard to observe with the human eye. Furthermore, liquid gas can leak in a variety of ways, including forming a puddle, dripping or spraying. In such situations, smart thermal cameras equipped with AI analytics can reliably detect anomalies and send instant alerts to responsible teams. With this, operation teams can then expedite the clean up or remedy the malfunction that is causing the leak.

Not visible to the human eye are liquid levels in tank batteries, which require use of liquid sensors to detect the levels. In this use case, AI-driven thermal imaging technology is a viable and low-maintenance supplement to the conventional monitoring sensors. Once installed, the thermal cameras can detect changing liquid levels. When installed at right settings, the same camera can also offer an additional use case in the form of leak detection.

Enhance Operational Safety and Security

The role of a modern operator is very challenging as it requires managing and juggling a large number of responsibilities. The foremost priority is, of course, operational safety and security, especially in cases of remote monitoring where operators may not be directly onsite. Operators are concerned with mitigating hazards and ensuring that employees are protected. Monitoring safety compliance with the human eye alone is not only inefficient, but also results in error. This is where AI-enabled analytics can step in and detect non-compliant behavior that degrades the overall security of the site and can result in OSHA fines.

One key example is the requirement for personal protective equipment (PPE) detection. By law, facilities are required to ensure that workers are properly suited in PPE. AI-enabled analytics can detect correct usage of hard hats, goggles, vests and flash resistant gear, and subsequently alert staff to take action in events of non-compliance. Similarly, fall detection can identify an abnormal movement that can result in injury and prompt personnel to respond quickly.

Aside from employee safety, smart cameras equipped with AI-enabled analytics can also detect optical leaks, such as methane and gas, without the need to stop operations. By monitoring tank levels, operators can prevent overflow of water, oil and other liquid tanks – even remotely. This also reduces the labor and risk of manual monitoring and avoids costly operational downtime by ensuring supply and that sensors are functioning normally.

Control Access and Manage Facilities Remotely

Managing facility access is important to ensure operations are not disrupted and that the premises are secure from any remote location. Smart camera technology can monitor visitors to identify intruders and can pinpoint unauthorized open doors. Certain applications are dedicated to recognizing license plates, streamlining the vehicles entering and exiting the site, and ensuring that cars at the facility are authorized to be there.

Facility managers can also assess the functionality of their equipment. Using AI-enabled analytics, predictive monitoring can help identify when machinery is not running properly and replace it before it stops working, or detect early signs of failure for tank and water levels. By reducing operational downtime, the facility avoids profitability losses caused by unforeseen closures.

Update Existing Surveillance Infrastructure

One of the fundamental challenges for operators is upgrading the existing infrastructure to support technologies. In several sites, installing new smart cameras can disrupt operations leading to massive financial loss. One way to overcome this hurdle is to retrofit traditional IP cameras with small gateway devices that can run AI-apps. The applications from open platforms can then be downloaded onto the gateway device to support several use cases.

The good news is that smart cameras and open platforms that offer AI-apps that provide integration opportunities into existing management platforms are already in use. The evolving AI-driven ecosystem provides a high degree of flexibility in deploying these devices as an alternative to traditional onsite monitoring technologies. As AI technology continues to progress, the digitalization and automation of oil operations will only advance.

Headline photo: AI-enabled smart camera application detects correct usage of personal protective equipment (PPE) to reduce danger and eliminate costly fines.

In his role as strategic program manager, Riwaj Sapkota focuses on business and product development of Azena’s oil and gas remote monitoring suite to help multinational upstream companies improve operational reliability and environmental performance with the help of AI video analytics. He has a decade of experience in IoT, connectivity and data science, enabling customers from various industries to capitalize on the digital transformation. Before joining Azena, Sapkota co-founded dstack.ai, a Germany-based AI start-up. Prior to that, he held various roles in product and business development at technology companies. Sapkota holds a master’s in electrical engineering and an MBA in Innovation and Business Creation. He can be reached at riwaj.sapkota@mail.azena.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.