As people around the world become increasingly concerned with sustainability, it’s vital that decision-makers in the oil and gas industry apply practical techniques to reduce emissions. Here are some ways digital technologies could help them.

Improved Methane Monitoring Can Reduce Emissions

Researchers continually look for better options for spotting methane emissions caused by leaks. They know that if people become aware of leaks sooner, the heightened awareness would help cut overall emissions.

Some newer solutions to reduce emissions by identifying leaks rely on laser spectroscopy, along with drones and small piloted planes that fly close to the potential sources of methane leaks. Other forward-thinking entrepreneurs have different approaches. Greg Rieker is a professor of mechanical engineering at the University of Colorado Boulder and the chief technology officer of LongPath Technologies. His solution is a frequency comb laser.

“We’ve used this system to pinpoint a leak to about a 5-square-meter area,” he says. “It’s a question of, when leaks start, seeing them and sizing them properly so we can alert an operator [that] there’s a problem. There are 20,000 wells out there. This is a Colorado-grown solution, using Colorado technology.” The system can continuously scan an area for weeks or months at a time, then provide a tally of methane emissions.

Commercial systems are also available to reduce emissions, such as the one recently adopted by Marathon Oil, which pledged to achieve a 60 percent drop in methane emissions by 2025, and an 80 percent reduction by 2030. It has 18 infrared cameras to assist with methane imaging. The chosen technology is an industrial Internet of Things (IoT) platform that provides colorized video clips of gas plumes that would otherwise be invisible.

“We believe that the technology, combined with our SCADA data, provides a more fulsome view of our operations and allows us to better understand and mitigate environmental impacts,” says Dana Wood, Marathon Oil’s environmental supervisor.

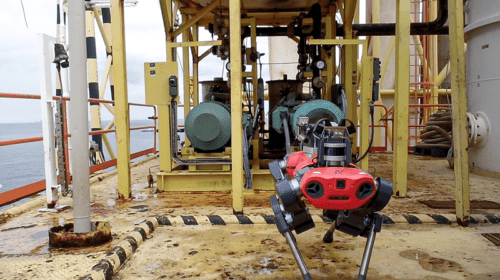

Smart Sensors Increase Oil and Gas Equipment Visibility

There is a connection between safety and efficiency in the oil and gas sector and the quality and reliability of equipment used. That link also extends to emissions. A 2021 report from the U.S. Energy Information Agency (EIA) noted that replacing old equipment can curb emissions because older equipment typically has more leaks. The report recommended replacing components early and switching from gas parts, to electrified parts, if possible, because they leak less gas while operating.

One way to get a clearer idea of when to replace components is to use smart sensors that monitor performance at the individual part and system level. Besides helping companies get a handle on emissions, that technology could cut operating costs. Statistics indicate going with a predictive maintenance approach could save companies up to 40 percent, compared to using the reactive maintenance model. In addition to minimizing money spent on unplanned repairs, this technology could curb catastrophic outages that halt operations.

Mika Tienhaara is the CEO of Rocsole, a company specializing in digital solutions for the oil and gas industry. He explained why such advancements are so vital, saying, “Burning of fossil fuels aside, fugitive emissions and venting due to malfunctioning equipment, leakages, and no or limited knowledge (lack of data) forms the largest emission source from upstream activities.”

“Depending on the exact type of source, emissions from these are in the range of 40 to 50 percent and, due to lack of data and digitized workflows, there is a bigger risk of running into failure. As such, it is in this area that digital solutions are needed to see significant emissions reductions.”

He then discusses what kind of issues site operators might encounter, saying, ”Examples of malfunctioning process equipment include multiphase separators, which have a risk of running into failure due to the lack of insights. Multiphase separators can, in many mature operations, have to deal with sand production, which can lead to erosion, corrosion and leakages. Having proper data is the starting point in avoiding these failures.”

Artificial Intelligence Supports Process Optimization

Oil and gas industry professionals have a daunting but necessary task when it comes to getting a handle on emissions. That’s because the efforts should ideally encompass the Scope 1 direct emissions, as well as the indirect Scope 2 and 3 emissions. Together, these make up 41 percent of greenhouse gas emissions globally. An increasing number of decision-makers are implementing artificial intelligence (AI) and machine learning to enhance their processes that cause excessive emissions.

In one case, that approach enabled an oil and gas operator to find ways to cut 500 million tons of Scope 1 and Scope 2 CO2 equivalent emissions, which constituted 30 percent of the company’s total emissions. A closer look revealed which efforts had the biggest influence on that 30 percent reduction.

More specifically, improving operational and energy efficiency accounted for 15 percent of the total, and a five percent reduction came through methods to curb flaring, fugitive and venting emissions. However, an impressive 60 percent of the total emissions reduction occurred due to switching to lower-carbon power and heat equipment and sources. The AI technology used also helped leaders at the company verify which process tradeoffs caused the biggest potential payoffs, which made it easier to set expectations before making changes.

In another example, a Texas operator with 200 wells applied AI to minimize operating costs. That, in turn, positively affected emissions. Letting AI analyze the data highlighted an overpumping problem in two-thirds of the company’s rod-lift wells. The company responded by using AI to automate setpoint management, which caused a 13 percent drop in greenhouse gas emissions.

This case study shows there’s no single solution to reduce emissions that brings universal success. Leaders must take the time to understand where the room for improvement exists. Then, they can apply the appropriate digital technology, whether AI or otherwise, to improve the likelihood of getting the desired results.

How Will You Apply Digital Technologies for Emissions Reduction?

The need to cut emissions across society as a whole will remain constant, especially with so much more emphasis recently placed on sustainability by the world’s leaders of business and politics. Digital technologies are not magic solutions that address everything ailing a company contributing too much to global emissions. However, as these examples show, such options are well worth consideration, especially once decision-makers are ready to act in meaningful ways.

Emily Newton is the Editor-in-Chief of Revolutionized, an online magazine discussing the latest industry innovations and trends.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.