As everyone from investors to the general public asks the oil and gas industry to get cleaner and more environmentally friendly, more and more operators are looking for options that do exactly that, while still working effectively. That is certainly true for mopping up spilled oil or oil-based drilling mud.

Regulators are in on the push as well. Texas Railroad Commission (TRRC) rules require total petroleum hydrocarbons (TPH) in the soil to be reduced below 10,000 ppm before that soil can be safely buried. This protects the water table below as well as plant and animal life above. And while those rules have been in place for a while, the Railroad Commission in recent years has increased its vigilance in enforcing these standards.

In cases where the treatment does not achieve the 10,000 ppm threshold, soil must be hauled off, a procedure requiring dozens of tractor-trailer trips that can add upwards of $80,000 to remediation costs. This also creates a list of ESG concerns including the emissions from trucks and the still-contaminated soil wherever it ends up.

And as prices for everything continue to rise, the best options must also be very cost effective.

Popular oil spill treatments use hydrogen peroxide, which has three main drawbacks. In the high concentrations required for the oil patch, it is highly toxic and requires special handling. Second, it is very costly when used in amounts large enough to remediate large mud tanks or oil spills.

But perhaps its biggest issue is the time it takes to get results – up to 90 days to break down especially heavy concentrations to 10,000 ppm.

Microbial Remediation Is Fast, Economically Efficient and ESG Friendly

Properly designed microbe mixes are proven to break down TPHs such as paraffin, asphaltenes and other petroleum hydrocarbons in saltwater disposal wells (SWDs), waterfloods, flowlines, tanks and elsewhere in the system.

Microbes are extremely cost-effective compared to H2O2 treatments. Most of the time, only a single treatment is required for spills because the microbes continue to thrive and reproduce as long as the TPHs provide them with food.

They work much more quickly than H2O2 as well. Instead of 90 days, field results show microbes reducing even heavy concentrations to well below 10,000 ppm in as little as 34 days.

Regulators such as the Railroad Commission see these naturally occurring microbes as so environmentally friendly that they do not require reporting or any special handling, unlike most oilfield chemicals. No protective gear is required at any point in the handling or management of these microbes.

In fact, anywhere microbes have been used in surface applications, observations are that plant life flourishes much more than before the treatment.

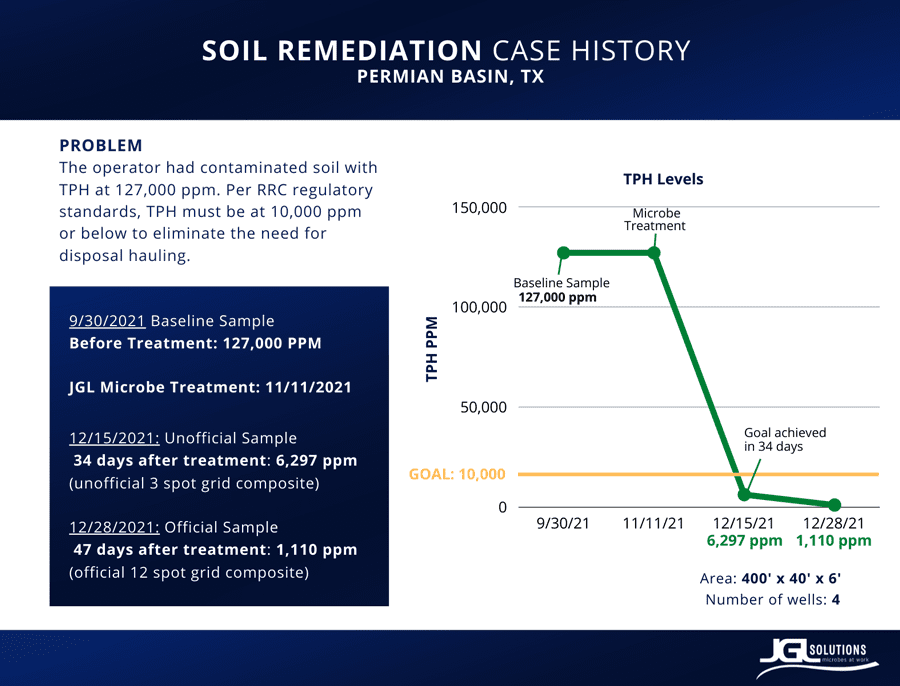

Below is an example of how this works in the field.

The Case Study

An operator had soil with very high contamination levels of 127,000 ppm in an area measuring 400’ by 40’ x 6’. There were about about 5,000 cubic yards of dirt to be treated. This would have been a very expensive amount to send off in trucks for disposal. The operator needed a solution that was less costly yet also more effective at reducing TPHs. After considering a number of alternatives, it decided to embark on a field trial to see if microbes would work as well in soil remediation as they have proven to work in SWDs and waterfloods.

For the trial, the operator divided the spill area into a grid with 12 sampling sections.

JGL experts tested the soil and formulated a microbe mix designed to efficiently break down those paraffins. The operator then spread the mix over the contaminated area.

After 34 days, the company preliminarily sampled about a third of the grid, at which point it found TPH levels already at 6,000 ppm, well below the required concentration, and accomplished much faster than with previously used methods.

At 45 days, they took the official sample, finding TPH levels further reduced, this time reaching 1,100 ppm. This is almost 10 times cleaner than is required. The microbes accomplished this with a single treatment in half the time, for about half the cost of H2O2 treatments, and with zero toxicity. Once the TPH concentration was remediated, no further monitoring or handling of the soil or the site was needed.

Cost Effective Solution

Microbes used in TPH remediation are naturally occurring from the start, which helps make the entire process environmentally and HSE friendly and ESG-aligned. They are effective, achieving their goals in about a month, and are cost effective in two ways. A single treatment is usually all that is required and, second, because the treatment works no matter how heavy the TPH concentration, there should be no need to spend tens of thousands of dollars trucking dirt to an approved disposal site.

Headline photo courtesy of JGL Solutions. Properly selected microbes have proven to treat scale and corrosion in water systems including tank batteries, as well as remediating on-ground oil spills.

Bill Lantz founded JGL Solutions in 2006 with the goal of providing the oil field with highly effective and sustainable solutions. He is a veteran of more than 30 years in the oil field.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.