CCS is touted as the solution to continued fossil fuel requirements, so cutting millions from costs and making wells hold more CO2 is vital to the process. Here’s how that can work.

Reducing greenhouse gases, especially atmospheric CO2, has become top priority for every industry as the world deals with global warming issues. Reduction can be done either of two main ways: Switching to cleaner fuels or capturing some of the CO2 emitted by fossil fuels.

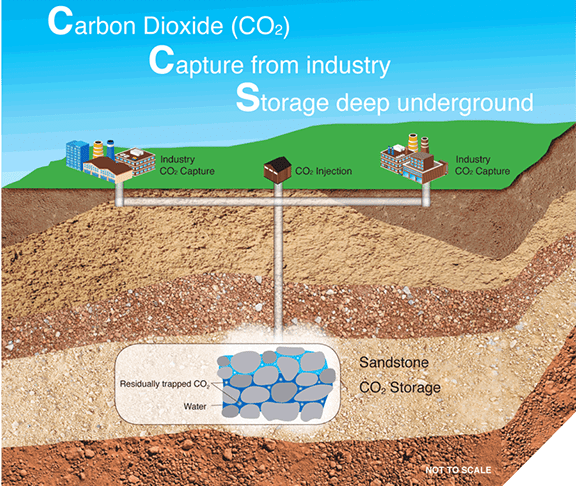

Since the EIA and other agencies expect the need for fossil fuels to continue for decades, carbon capture and sequestration (CCS) will be a vital component in the global warming issue for at least that long. CCS involves capturing the airborne CO2 and injecting it deeply and securely into subsurface formations.

In what some see as an irony, the oil and gas industry is uniquely positioned to remove and store some of the CO2 its products produce because drilling and connecting to deep wells are key functions in both operations.

This article will discuss the challenges with ramping up CCS to scale, the very high costs involved, and how adjusting wettability to match the formation into which CO2 is injected can mitigate costs of permitting and installation.

A Problem of Scale

The U. S. currently emits 5.3 billion tons of CO2 per year, and there are only two licensed CO2 disposal wells, both of which are in Illinois. Securing the Class VI permit for such wells is difficult and costly. Only two states, Wyoming and North Dakota, have been granted primacy to issue permits themselves instead of relying on the EPA. North Dakota has recently permitted two more Class VI wells, but the permitting process is slow and costly. The EPA estimates it will take two years to gather, synthesize and submit information for any initial applications that come in for future wells.

The oil and gas industry already geologically sequesters CO2 for enhanced oil recovery (EOR), at the rate of approximately 100,000 tons per day, according to EPA figures. This carbon capture and utilization (CCUS) comes from underground sources, usually natural gas fields where CO2 is a byproduct. Little to no anthropogenic (human generated from burning fossil fuels) CO2 is currently involved in CCUS.

Should CCUS methods in EOR switch to anthropogenic CO2, it could produce carbon-neutral to carbon-negative oil, research has shown (Lopez et. al. 2019). But would it be enough? In the last 40 years, CCUS fields have sequestered 600 million tons of CO2. When compared to the 5.3 billion tons the U. S. emits every year, it is clear that CCS is going to be critical to reaching sequestration goals.

Combined with the fact that there are only two CCS (Class VI) wells licensed in the U. S., it is obvious that much more capacity is needed before any difference is made in reducing atmospheric CO2.

Cost and Complexity in New Class VI Wells

In addition to the time involved, there is great expense in permitting and drilling new Class VI wells. Anything that could improve the process in both areas will be a key to the expansion and effectiveness of these wells.

Here is where experience in the effects of formation wettability will pay dividends to companies and to the planet. First, it’s important to understand the mechanics of a CCS well.

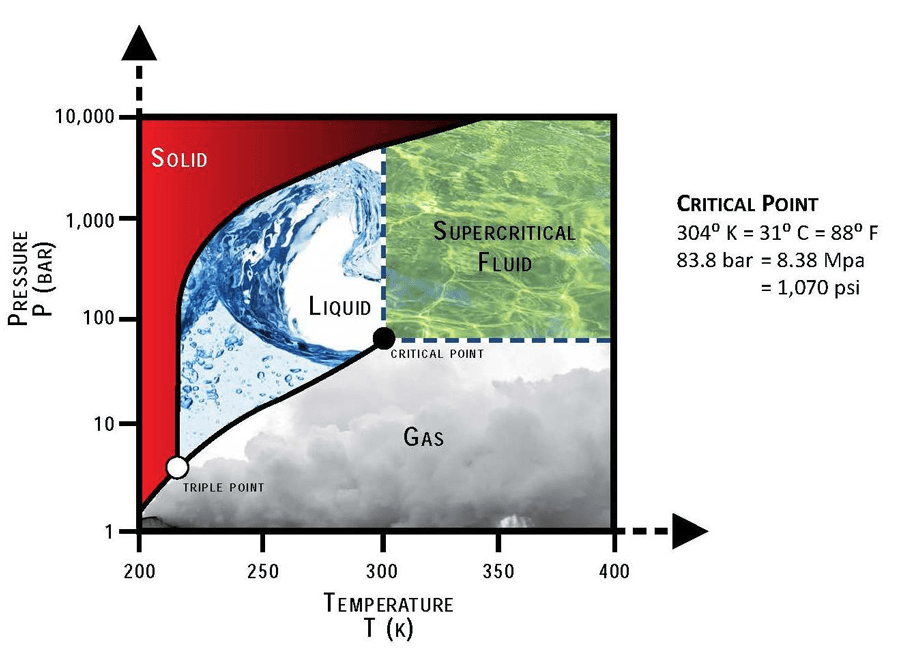

Sequestration will bury CO2 in the supercritical state since that compressed form will be required to maximize underground storage. Supercritical CO2 is compressed into a liquid at pressures greater than 1070 psi. To maintain this pressure in storage, the site must be deeper than 3,000 feet. Supercritical CO2 is the standard form used in CCUS. It is transported in pipelines, so the oil and gas industry not only has relevant experience, it can also make use of at least some existing infrastructure for transportation.

Sequestered CO2 is held in place by four mechanisms: 1) stratigraphic trapping under low permeability caprocks or strata, 2) capillary trapping or the resistance to the buoyancy-driven upward movement of the less dense supercritical CO2 by the capillary forces in pore throats, 3) CO2 solubility and 4) mineralization. The relative contribution of the trapping mechanisms changes over time, but the stratigraphic and capillary mechanisms are usually the most important factors.

The Role of Wettability and How It Reduces Costs and Maximizes Storage

The distribution of CO2 over time is largely controlled by the wettability of the system (Bachu, 2013). Wettability is the property of the liquids (CO2 and brine) to adhere to the rock. In the vocabulary of petroleum engineers, it is usually expressed as capillary pressure or relative permeability. Wettability also controls the storage capacity, which can range between 31 and 85 percent of the pore space in the primary target of sequestration, which is sandstones (Burnside and Naylor, 2014). The storage capacity impacts the required well density, or spacing between wells, while wettability impacts the injectivity of individual wells.

Before explaining more about the benefits of wettability control, more explanation of the mechanics of the storage process is needed. This affects the permitting process because one of its key elements is the initial estimate for the area of review (AOR), which is essentially the surface footprint of the subsurface storage plume. This estimate will define where to gather input data to model the plume’s reach. All the subsurface data – porosity, permeability, mineralogy, rock mechanical properties, faults, all wells and potential conduits for leakage, the stratal architectures for the storage zone and the overlying strata, including any underground sources of drinking water (USDWs) – are mapped up to the surface.

All this data is used to model the proposed CO2 injection, including the pressure impact from injection, and to define the AOR. The EPA expects it will take a year or two to gather, synthesize and submit the initial application and the calculated AOR. Further ongoing work will then be required to secure the permit to inject and approve the closure plans, which include identifying and mitigating potential CO2 leaks.

The sequestration site will then be monitored for decades after closure. It costs significant dollars to characterize, model and monitor every acre during injection and to continue monitoring after closure. For example, the post-injection cost per acre for monitoring a 5,000 acre project is approximately $25 million, or $5,000 per acre over 50 years, according to Yosemite.epa figures. Any emergency or remedial response could add $6 million per event.

Why Monitoring Is Required – and Critical

The challenge is that CCS injection wells will initially produce a column of CO2 that mushrooms over time as the buoyant CO2 spreads laterally below the caprock as shown in figure 2. The injected plume and associated initial AOR grow with time. This is because the injected CO2 moves upward and outward, creating a much larger final AOR. As the area grows, the cost of monitoring – and therefore the cost of the whole project –increases exponentially.

Also, as the figure shows, the initial storage capacity of 60 percent reduces to 10-15 percent near the injection site (red vertical line) as the CO2 moves upward. This 10-15 percent is the residual trapping of CO2, which cannot move or leak, making the CO2 trapped by residual saturation the safest portion of the stored material. The CO2 is trapped by residual saturation, which substantially reduces risk and the estimates of financial responsibility associated with storage. The best outcome for storing CO2 is to have high residual saturation coupled with the smallest surface footprint and AOR. These characteristics will produce the most cost-effective solution. Just as ESal’s proven wettability solutions have helped E&Ps double their production from existing formations by releasing more trapped oil, that same wettability optimization can benefit CCS wells in two ways:

First: Improving the receiving formation’s relative permeability can restrict the lateral mobility, reducing the AOR. Industry experts say this could save tens of millions of dollars in mitigation costs.

Second: Altering the relative permeability can improve the formation’s CO2 holding capacity. This makes each CCS well that requires a Class VI permit operate longer, which reduces the number of wells needed.

Conclusion

The nation will need, in short order, vastly more CCS Class VI wells at great cost to permit and install, if this process is to make a dent in anthropomorphic CO2. Using wettability to reduce costs and increase efficiency can make this process more affordable to everyone involved.

Dr. Geoffrey Thyne is an expert in increasing recovery by manipulation of water chemistry. Dr. Thyne began his career in 1979 as a research geochemist at the Arco Oil and Gas research facility in Plano, Texas. He received his PhD in Geology from the University of Wyoming in 1991 and taught at California State University-Bakersfield and the Colorado School of Mines until 2005. Dr. Thyne returned to the University of Wyoming in 2006 at the Enhanced Oil Recovery Institute where he was lead scientist for the DOE-funded Big Sky Carbon Storage Project in Wyoming. During his time at EORI, he became immersed in the possibilities of changing water chemistry to improve oil recovery, studying the process in the laboratory and the field. In 2012, Dr. Thyne left EORI and formed ESal in 2013.

Vladimir Ulyanov is an expert in quantitative economic and financial analysis, with more than five years of experience at various technological startups. At ESal, he is involved in evaluating tertiary oil recovery and carbon capture and storage projects.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.